Profile

Lightweight structures engineering with textile-reinforced composites offers numerous advantages over conventional designs. Here, function-integrating lightweight structures using multi-material design are particularly significant. Mainly the high stiffness and strength with low weight, the good damping and crash properties, the great variety of textile processes and structures as well as the cost-effective production with high reproducibility, the suitability for high-volume series production and the good recyclability really predestine this young material group for future lightweight applications within different industries.

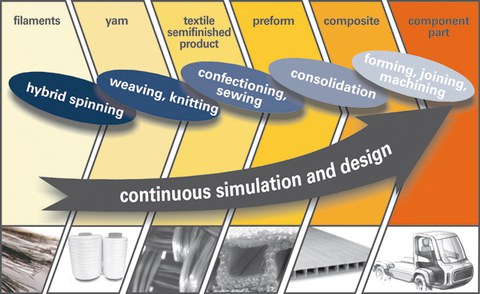

During developing textile-reinforced composite parts for complex applications, the reinforcement and the component structure have to be fitted to one another. This is bound to involve a close entanglement of the design processes of both material and component. Thus, research at SFB 639 is focussing on a continuous treatment of the whole process of developing lightweight structures in multi-material design using textile composites (see figure). The isolated consideration of singular problems, which has been common so far, will not lead to a fundamental gain of knowledge when tackling such a strong interaction of the local and the global structure (from filament up to component part). Only with a continuous, synchronised approach, the high lightweight potential given here can be fully exploited.

The issues arising during the continuous investigation will be addressed by means of selected basic components. In particular, textile near-net-shape structures and sandwich structures, handling equipment with process-adapted kinematic systems, textile-compatible joining methods and joining elements, textile-reinforced compliant structures as well as composite components with integrated sensor networks will be investigated. These representative components permit realising different scenarios of application for multi-material design. Within the process studies for the recycling of the new textile composites, also recycled material is to be incorporated into the new parts during pressing.

SFB 639 with its inherent network approach offers an excellent platform to ensure the interlock required here. The spatial and temporal concentration and the interdisciplinary communication allow for the development of process specifications and design rules which provide - besides the reduction of costs - a significant performance gain and reduction of development times of textile-reinforced parts. Particularly, this requires the continuous application of up-to-date simulation and design methods, because they permit predicting the properties of intended products without extensive structural tests, and the textile structures can be designed in a load-adapted manner already during an early concept phase. Only the outlined approach makes an efficient development of new lightweight products possible and, thus, help this innovative, young group of materials to get thoroughly accepted in various fields of application.