Subproject B2: Calculation of stress concentrations for multi-layered knitted fabrics and textile-reinforced sandwich systems with insert elements

Supervision

Dr.-Ing. Martin Lepper

TU Dresden

Institute of Lightweight Engineering and Polymer Technology

01062 Dresden

Germany

Phone: +49 351 463-38147

Fax: +49 351 463-38143

Abstract

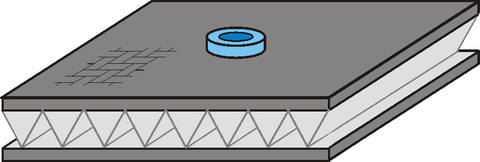

The focus of this subproject is set to the development of design methods for necessary cut-outs and inserts (e.g. joining elements or bolts) in anisotropic structures made of multi-layered knitted-fabric composites as well as textile-reinforced sandwich systems (see figure). In order to precalculate the induced critical stress concentrations of such textile-thermoplast structures and assess them with realistic failure hypotheses, textile-adapted simulation models are developed. They are validated numerically as well as experimentally.

Figure: Textile-reinforced spacer-fabric structure with insert

Enhancing the analytical models developed in the first project phase for quasi-infinite, plane multilayered structures with inserts, which were based on the classical lamination theory and on an extended approach according to Mindlin/Reissner (First order shear deformation theory), a textile-adapted simulation method for the stress and strength analysis on the basis of super elements and the sub modelling technique is to be developed in the second phase. At this, coupled analytical-numerical as well as purely numerical methods are applied and explored with respect to their usability in the future demonstrator phase. Thereto, the analytical solution methods acquired so far have to be extended upon composite structures with a finite boundary, and methods to couple them with special elements incorporating insert influences have to be included in the finite-element analyses.

Furthermore, enhanced notched strength criteria are to be developed. They are based on the observation that stress concentrations well above the nominal strength do not necessarily initiate failure when occurring in a limited vicinity of a notch. Continuing the research within the basis phase, e.g. on the point stress criterion (PSC), these notched strength criteria are to be enhanced such that they permit more detailed conclusions on the failure behaviour by a layered failure assessment using textile-adapted criteria. This also includes developing extended methods for a textile-adapted choice of the evaluation point or evaluation line with respect to the cutout. Furthermore, the approach, which is originally formulated for the load case open-hole tension (OHT), has to be transferred to other load cases such as bending or "filled-hole tension" (FHT).

The theoretical results are validated experimentally by accompanying load tests. Additionally, primary studies on the application of the obtained methods for stress concentration analyses and notched strength assessments onto textile-reinforced composite components with cut-outs and inserts under highly dynamic loads are planned.

The developed models and criteria will be used in the subsequent demonstrator phase to derive dimensioning criteria for the design of textile-adapted joints in project groups B and E.