Energy saving in vacuum handling by reduction of dead volumes by means of bionic active principles

Research Task/Objectives

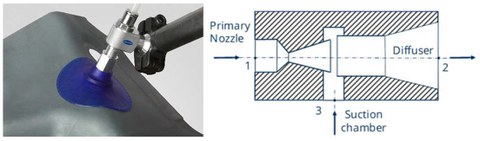

The pneumatic vacuum generators, which are also called ejectors, generate a lower static pressure level at the end of the nozzle than the ambient pressure level, causes suction effect. Ejectors are commonly used for handling systems because of their compact design, relative simplicity, fast performance, low capital cost, flexible application, and required little maintenance, as they do not have moving parts. However, compressed air systems generally have an efficiency of less than 20%.

Due to rising cost of energy, worldwide mitigation of carbon footprint and social demand for sustainable and renewable orientation of industrial activities, efficient energy usage is a vital issue for producing companies. In European Union 10% of the industrial used electrical energy is allocated to compressed air generation. Therefore, the energy efficiency of vacuum handling technology is a notable issue in the development of sustainable and efficient manufacturing process.

Approach/Results

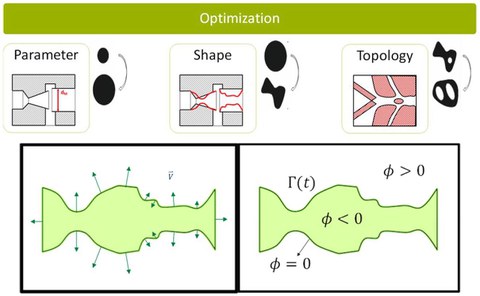

In the course of the research work, development of an innovative ejector principle that works significantly more efficiently than known ejectors in terms of supply pressure and mass flow is considered. Research on the achievable performance potentials of low-pressure ejectors with regard to energy efficiency and suction power by the use of numerical method, shape, and topology optimization is conducted. This helps to find an optimum geometry for design and manufacturing of ejectors and provides unconventional solution search for boundary outline. Further contribution to the conversion of biological suction systems into industrially usable vacuum suction pads is of the interest.

The implementation is carried out by the scientific collaboration among Chair of Fluid-Mechatronic system Dresden, Fa. Schmalz GmbH, Botanischer Garten Freiburg, and Institute of Machine Tools and Production Technology Braunschweig.

This research was funded by the German Federal Ministry of Economic Affairs and Energy (Ref. No. 03ET1559D). The authors are responsible for the content of this publication.