Cost-efficient electro-hydraulic compact drives (ECD) using plastic components

Research Task/Objectives

Commercially available hydraulic components for use in ECDs are designed to operate at high pressure and high power, and thus are efficient in terms of energy and costs. However, costs no longer scale with performance below a power of about 3 kW or below a force of 10 kN, as the design scaling of conventional components is often limited by manufacturing and mechanical issues. Therefore, electro-mechanical drives dominate this drive segment.

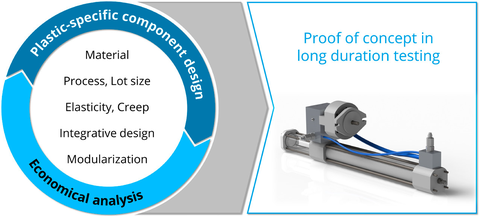

The use of plastics can help to reduce the costs of low-power hydraulic components due to their low-cost production and assembly. This can make a decisive contribution to closing the gap between hydraulics and pneumatics. Within the scope of a potential study, ECDs made of plastic components are designed, manufactured and tested and an economic analysis is carried out in the context of production processes suitable for mass production.

Project topics for the investigation of plastic components in compact drives

The contribution is based on the project "Cost-efficient electro-hydraulic compact drives (ECD) using plastic components", initiated and financed by the Forschungsfonds Fluidtechnik within VDMA (FKM No. 7046700).