Increasing the resource efficiency of cleaning processes in food industry with modular model soil - ReMoVe

The industrial cleaning of food processing equipment is frequently realized as automated process. The manufacturers of such equipment usually perform cleaning tests to design and optimize these cleaning processes. Real products can hardly be used for these cleanability tests, as they need to be manufactured in certain production steps, and their cleaning monitoring is a separate challenge. If only easy-to-clean test soils are used, only basic cleanability can be demonstrated. To ensure product safety, the final cleaning processes are usually oversized. This results in unnecessarily high consumption of drinking water, energy and chemicals and produces high amounts of wastewater and high CO2 emissions for energy supply.

Objective

In mechanical and plant engineering, current testing procedures involve the use of easily removable test soilings to design cleaning processes before the start of production. However, these tests often fail to accurately replicate the cleaning behavior of real products. Real products are typically unsuitable for testing purposes due to their reliance on specific manufacturing steps and their difficulty of detection. To ensure product safety, cleaning processes in food production are often over-designed, resulting in excessive consumption of drinking water, energy, and chemicals, as well as the generation of large volumes of wastewater and high CO2 emissions during energy provision.The objective of the research project was to develop readily applicable, reproducible, and easily detectable model soils using simple raw materials to simulate various cleaning behaviors observed in food, focusing on dairy products as an example. The future utilization of these model soils will facilitate the environmentally friendly and resource-efficient planning and optimization of industrial cleaning processes at the machine/plant manufacturing stage.

Work steps and methods

As part of this research project, seven dairy products (cream cheese, high-protein pudding, yogurt, pudding, quark, processed cheese, soy yogurt) were investigated regarding their cleaning behavior in a closed system (flow channel). The synthesis of the model soils was initially based on the chemical composition of the dairy products and culminated in the use of milk as a base. The variation of thickening agents and other standardized raw materials from milk processing was conducted to adjust the necessary tenacity during cleaning.

In order to select suitable model soils for prospective cleaning tests, methods were evaluated for their suitability in characterizing the cleaning behavior of specific food soils. The persistence of soiling was determined through extraction measurements and rheological tests. Additionally, the interaction behavior between the soiling and the cleaning liquid was assessed by determining the change in layer thickness and mass.

Results and discussion

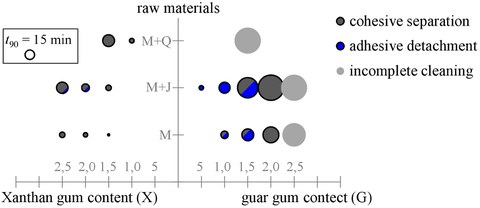

Based on the identified cleaning behavior of the selected dairy products, a portfolio of model soilings was developed. Milk served as the basis, and the cleaning mechanism and persistence were adjusted by varying the thickening agents, namely xanthan gum and guar gum, while also introducing yogurt and quark. The focus during the synthesis of the model soils was on mapping cohesive separation and adhesive detachment.

Viscous displacement of the dirt layers was not observed in the dairy products tested when in contact with water at 25°C. A general conclusion regarding the cleaning behavior could not be drawn from the chemical composition of the analyzed dairy products. For primarily cohesive separation in soiling, the average peel force correlated with the cleaning time. Moreover, this force provided insight into the cleaning mechanism of the specific soiling under consideration.

Determining the rheological properties of swelling layers allowed us to make statements about the stiffness and the ratio of viscous and elastic parts of a dirt layer after contact with cleaning fluid. It was observed that there is a correlation between cleaning time and changes in the rheological target values over time. Furthermore, the change in the relative layer thickness or mass of swellable soiling correlated with each other and enabled initial assumptions about the cleaning success. However, the interaction capacity alone was not a sole measure for predicting cleaning behavior.

Overview of the cleaning time t90 and the cleaning mechanism of the model soils as a function of the raw materials (milk M, yoghurt J, quark Q) and the thickener content. Circle diameters represent the required cleaning time in the flow channel.

Publications

During three online sessions conducted with the project's accompanying committee, the research findings were communicated and discussed. Initial project results were made accessible to a wide readership within the industrial sector through publications in the specialized journals “Rundschau für Fleischhygiene und Lebensmittelüberwachung” and “Molkerei-Industrie”, as referenced in Helbig et al. (2023a, b). Furthermore, another publication is scheduled in the specialized journal 'Der Lebensmittelbrief' in 2024, presenting additional project outcomes. Additionally, during the annual general meeting of the Gesellschaft Deutscher Lebensmitteltechnologen e.V. (GDL), a presentation on soil structure-based cleaning of facilities (October 13, 2023) highlighted the issues and drew attention to the project.

- Helbig, M.; Hovorka, K.; Schmidt, C.; Zahn, S., 2023a. Reinigung im Visier: Analyse des Reinigungsverhaltens von Milchprodukten zur Entwicklung von Testverschmutzungen, Rundschau für Fleischhygiene und Lebensmittelüberwachung: RFL, Jg. 75, Nr. 6, S. 208-211

- Helbig, M.; Hovorka, K.; Schmidt, C.; Zahn, S., 2023b. Reinigung im Visier: Analyse des Reinigungsverhaltens von Milchprodukten zur Entwicklung von Testverschmutzungen, Molkerei-Industrie: Fachmagazin für die Milchverarbeitung, 2023, Nr. 7, S. 26-30 https://www.moproweb.de/blmedien-epaper/molkerei-industrie-07-2023/

Conclusion

Selected model soils were successfully tested as a test product in an industrial environment, both within a closed system and by applying them with a new designed scraping-nozzle to enable localized assessment of cleaning-critical areas. Machine and plant manufacturers can now precisely select a model soil based on the anticipated properties of the milk-based contamination. This allows for testing and optimizing individual components, as well as the interaction between cleaning technology, cleaning parameters, and the contamination, even before the start of production. The fundamental procedure for developing model soil can be applied to other product groups across various industries, ultimately facilitating a more environmentally friendly design of cleaning processes within the entire food sector.

Project funding:

The project ReMoVe is supported by the German Federal Environmental Foundation (Deutsche Bundesstiftung Umwelt DBU) in the topic 2 "climate protection and energy".

Project duration:

03.2021-08.2023

Project management and contact:

Project leader: Prof. Jens-Peter Majschak

Project management: Dipl.-Ing. Manuel Helbig

© Nils Eisfeld

© Nils Eisfeld

Cleaning Technologies

NameDipl.-Ing. Manuel Helbig

Wissenschaftlicher Mitarbeiter

Send encrypted email via the SecureMail portal (for TUD external users only).

Partner:

Chair of Food Engineering at the Institute for Natural Materials Technology of the Technische Universität Dresden