Experimentally supported basis models for a feasible numerical cleaning simulation

To achieve reproducible results in regular cleaning applications, automated and permanently installed cleaning devices (cleaning in place, CIP cleaning) are used. Due to the lack of suitable design tools for optimisation, an over-dimensioning of the cleaning process is often taken into account. This leads to a reduction in productivity and a waste of water, chemicals and energy.

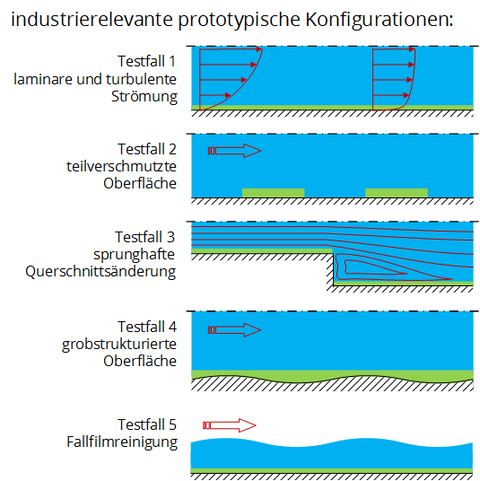

The aim of the project is to develop or enhance numerical models for the different cleaning mechanisms of soils, which are characterised by a good prediction quality in determining the cleaning time as well as viable calculation times for SMEs. The proposed solution combines a flow simulation (CFD) of the cleaning fluid for any desired shape of the product to be cleaned with a boundary condition that models the behaviour of the soil. This is a prerequisite for optimising a wide range of cleaning processes by using numerical simulations in the future. The models, which depend on the mode of failure, are to be developed and tested on geometrically simple test cases by using the knowledge and measurement data gained in previous projects, supplemented by further experimental and numerical investigations.

A cleaning prediction based on numerical simulation enables the industries to solve a wide range of problems in the field of cleaning, both reducing the efforts for process development and the resources required to operate the cleaning process.

Project results:

The aim of the project was to develop models for different cleaning mechanisms that have a good prediction quality of the cleaning time and computation durations that are practicable for SMEs. The approach combines a flow simulation for an arbitrary shape of the part to be cleaned with a boundary condition that models the behaviour of the contamination.

For cohesive separation/diffusive dissolution, a wall function was added to the model because the flow and mass transfer boundary layer differ by an order of magnitude. Cleaning simulations with a 32-fold reduction in resolution provided consistent prediction quality.

No cleaning success was achieved for viscous shifting at room temperature. An isothermal test at elevated temperature would not correspond to industrial practice. Therefore, a flow model with temperature-dependent coefficients was generated and a model for cleaning prediction was used, which can

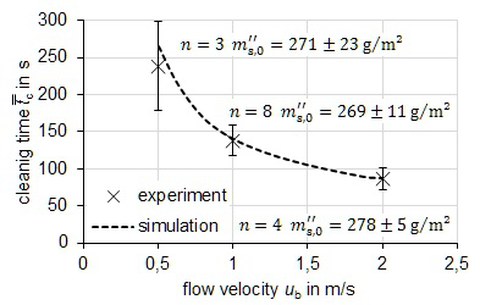

For adhesive detachment, the swelling process and binding forces were analysed and numerically modelled. Using a diffusion model, the diffusion of water into the soil layer was calculated and the local water mass fraction determined. Based on the calculated flow a comparative stress is calculated from the acting pressure and shear. If this exceeds the adhesion forces, detachment occurs.

The model was successfully validated using the cleaning times for three test cases.

In view of the challenging objective of generating models that can be parameterised exclusively from laboratory tests, the model for adhesive detachment was extended for cohesive separation. First results are promising. The model thus represents the basis for the transition between cleaning mechanisms, which is the focus of the follow-up project.

Project financing:

This research project is supported by the Industrievereinigung für Lebensmitteltechnologie und Verpackung e. V. (IVLV), the Arbeitsgemeinschaft industrieller Forschungsvereinigungen “Otto von Guericke” e. V. (AiF) and the Federal Ministry of Economic Affairs and Energy (IGF 19968 BR).

Project duration:

02/2018 – 07/2020

Project management and contact:

Project leader: Prof. Majschak

Project manager: Hannes Köhler

© Köhler

© Köhler

Cleaning Technologies

NameDr.-Ing. Hannes Köhler

Research Field Coordinator

Send encrypted email via the SecureMail portal (for TUD external users only).

Cooperation partner: Technische Universität Dresden, Institute of Fluid Mechanics, Chair of Fluid Mechanics