Cutting Edge Research

What strategies can be implemented to enhance the efficiency and sustainability of production processes? And how can processes such as cleaning, welding and sealing be further improved? These are the driving questions that the Chair of Processing Machinery/Processing Technology at TU Dresden seeks to address through its research activities. Through interdisciplinary approaches, the chair develops innovative solutions for the production of consumer goods - from the processing of fiber-based materials to the development of flexible and resource-saving cleaning processes.

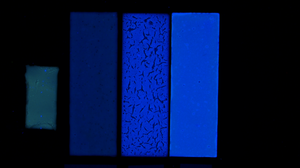

© M. Helbig

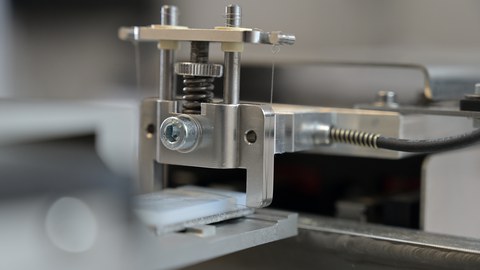

© M. Helbig

Research profile

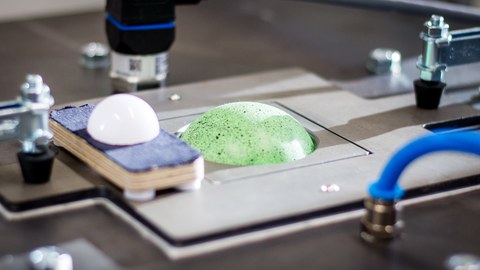

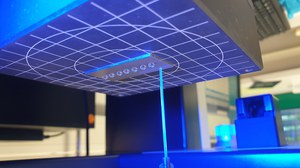

Our work focuses on the development of innovative solutions that influence both the functionality and design of machines. The processing behavior of the products and the time restrictions of the processes significantly determine the design of machines. Our research aims to identify the influencing parameters of these processes, to quantify their influence and to develop models that form the basis for the conception and design of modern processing machines.

One example of our work is the simulation of the interaction between the processed material and the machine, including the integration of mechatronic function groups. This makes it possible to tap into efficiency potential and at the same time realize the flexible, resource-efficient and highly integrated process chains that are essential in modern manufacturing. This is no longer just about high processing speeds, but also about the development of flexible, sustainable solutions that promote the careful handling of complex material systems - as required for the production of a wide range of consumer goods.