Oct 02, 2025

Dr.-Ing. Paul Penzel from ITM is honored for his dissertation with the Innovation Award of the Industry Club Saxony 2024

Dr. Penzel (2nd left) together with J. Gerken (Chancellor of TUD; left), G.-L. von Breitenbuch (Minister of State, Saxon State Ministry for the Environment and Agriclture; 2nd right), and U. Franzen (President of Industrieclub Sachsen e.V.; right)

Paul Penzel was awarded the Innovation Prize of the Saxony 2024 Industrial Club on 30 September 2025 for his dissertation " Modelling and development of bond-optimized textile concrete reinforcements for influencing the bond and failure behaviour in concrete matrices in a targeted manner" . The prize is endowed with EUR 5,000 and is awarded annually to a TU Dresden graduate.

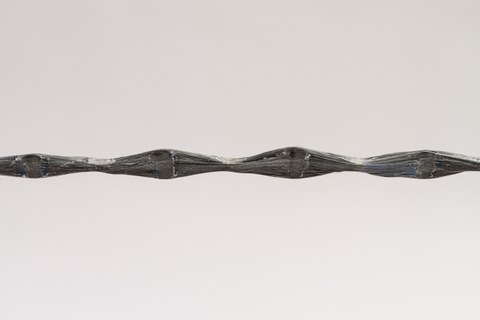

Representation of composite-profiled textile concrete reinforcement

The decision to award the Saxony 2024 Industrial Club Innovation Prize was made by a jury in the summer of 2025. The Innovation Award was presented on September 30, 2025 during a festive event at Schloss Eckberg in Dresden.

Laudatory speech by Prof. Dr. Ing. habil. Chokri Cherif

Dr.-Ing. Paul Penzel studied mechanical engineering at the ITM of TU Dresden from 2015 to 2020, specializing in textile mechanical engineering, and has been actively involved in the development of carbon concrete as a Student Assistant since 2017. He completed his studies in 2020, accompanied by a Germany Scholarship. In his work as a Research Associate, he has conducted fundamental research into carbon reinforced concrete, with his innovative contributions being recognized with the Techtextil Innovation Award 2024, among others. Since June 2025, Dr.-Ing. Paul Penzel has been coordinating interdisciplinary research activities and knowledge transfer as Scientific Director of ITM at the Chair of Textile Technology.

Interview between J. Gerken (Chancellor of TUD; left) and Dr.-Ing. Penzel (right)

The award-winning dissertation addresses one of the most pressing challenges in the construction industry: the development of resource-efficient, durable and economically viable building materials that also help to reduce CO₂ emissions. The recent collapse of the Carola Bridge in Dresden, a tragic example of the ageing and structural weakening of existing infrastructures, emphatically underlines the need for innovative solutions for durable and sustainable building structures. Mr. Penzel's scientific work is particularly topical in view of the increasing pressure on existing infrastructures, dwindling resources and the urgency of climate-friendly technologies. Textile-reinforced concrete with carbon reinforcement is regarded as a key technology for sustainable construction. However, the insufficient efficiency of the force transmission between the carbon reinforcement and the concrete matrix has so far stood in the way of widespread application. Conventional reinforcement structures require long anchorage lengths and lead to material-inefficient oversizing. This increases construction costs, makes processing more difficult and limits economic use, especially for small and medium-sized companies. Dr.-Ing. Penzel has fundamentally analyzed and solved this problem in his dissertation. With the development of novel, profiled textile concrete reinforcements based on material-specific profile geometries, he succeeded in achieving a significant increase in the composite properties while at the same time maximizing the mechanical potential of the carbon fibres. The resulting reduction in overlap lengths from approx. 1 m to just 0.1 m marks a quantum leap in application efficiency. Particularly noteworthy is the integrated technology-oriented research approach, which includes both the theoretical modeling of yarn profile geometries and the development of production processes suitable for industrial use. Through his developments, Mr. Penzel has thought about and significantly prepared the industrial transfer of his results. The proof of technology carried out as part of the dissertation impressively demonstrates the mechanical and economic advantages over previous reinforcement solutions: Up to 55% material savings and around 40% reduction in material costs with identical load-bearing capacity - a milestone in the quest for cost-efficient, ecological and durable building materials. This potential means that significant market barriers to the widespread introduction of textile carbon reinforcement can be overcome. Last but not least, Dr. Penzel's work demonstrates a high level of scientific depth and breadth. The combination of experimental validation, application-oriented modeling and practical economic analysis gives the work exceptional substance. The results have already been documented in numerous scientific publications, international conference papers and patent applications. This not only demonstrates the level of innovation, but also the great scientific and industrial interest in the solutions developed.