High-performance asphalt with composite-optimized textile reinforcement and integrated sensors

The "HighPerAsphalt" research project is investigating the world's first durable, sustainable and intelligent asphalt construction method for use in road construction, which is designed to withstand increasing mechanical and climatic stresses in the long term. The aim is to significantly extend the service life of the road pavement by using a non-metallic textile reinforcement with integrated sensors in the deeper asphalt base layer.

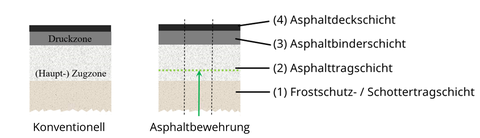

High axle loads in road traffic lead to degradation of the asphalt pavement, whereby climate- and traffic-induced tensile and compressive stresses occur in the different asphalt layers, especially in the lower asphalt base layer. These stresses cause microcracks that can spread into the surface course over time. The penetration and subsequent freezing of water into these microcracks promotes progressive damage to the asphalt superstructure, which can lead to the formation of potholes and structural road damage in the long term. To increase the fatigue resistance of the road pavement, robust textile grid structures are to be integrated into the lower asphalt base course as reinforcement. The non-metallic reinforcement structure absorbs the forces acting on the pavement when it rolls over and reduces the formation of cracks accordingly.

(Schematic) Layer structure of asphalt pavement in conventional road construction with compression and tension zones (left) and with textile non-metallic reinforcement (right)

In order to ensure a high bond strength between the asphalt mastic and the textile reinforcement structure, the reinforcing filament yarns are to be profiled and processed into a structurally stable, grid-like surface structure. A fiber-based sensor system will be integrated into the textile reinforcement. This will monitor the mechanical loads and the traffic situation. On this basis, predictions on the fatigue behavior of the asphalt base layer are to be made and structural maintenance measures planned at an early stage.

Lattice-like non-metallic reinforcement structure consisting of profiled carbon yarns

Other project partners are working on the development of a functional, highly rigid, temperature-reduced asphalt, a suitable installation method for the textile reinforcement in the asphalt and an AI-based evaluation method for the fiber-based sensor technology for fatigue prediction and load monitoring of the road pavement or asphalt base layer.

The new type of textile-reinforced pavement reinforcement is intended to extend the service life of the asphalt base layer from 30 years to 60 years. The aim is to save around 32% of construction and maintenance-related costs and around 40% ofCO2 emissions. The combination of reinforcement and sensor functionality offers a high economic benefit and enables non-destructive, large-scale, data-based condition monitoring of road infrastructure for the first time.

December 2025

In December 2025, the kick-off event for the HighPerAsphalt research project took place at the Institute of Textile Machinery and High Performance Materials Engineering (ITM) at TU Dresden.

Representatives of all project partners - ITM, Institute for Road Construction (ISS), Johne & Groß GmbH, Wolf Straßen- und Tiefbau GmbH, dresden elektronik ingenieurtechnik gmbh and TECHiFAB - took part in the meeting. Together they visited the ISS test field and the ITM test field with various textile machines.