Prenanoc

Modified highly ductile and electrically conductive carbon fibres

01.09.2017-31.08.2018

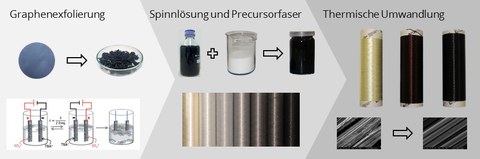

Working scheme of the project Prenanoc

subprojects

As part of a DFG research project (Head: PD Dr.-Ing. habil. Robert Böhm, Prof. Dr.-Ing. habil. Dipl.-Wirt. Ing. Chokri Cherif, Prof. Dr. rer. nat. Xinliang Feng, Prof. Dr. rer. nat. Hubert Jäger), it was shown that graphene-modified carbon fibres can be produced using graphene/PAN dispersions with long-term stability. With the identified process-structure relationships for the spinning process and the thermomechanical conversion, rovings that are 100 times thicker than the previous state of research can now be produced.

The gained results enable for the first time the production of graph-modified carbon fibres on an industrial scale. Among other things, the stability of non-functionalized graphene dispersions in DMF with a concentration of 0.05 to 0.5 weight percent was significantly increased. By a further functionalization graphene DMF dispersions with a stability up to one month could be produced. The functionalized and non-functionalized graphene dispersions of different mass concentrations can all be used for spinning precursor fibres.

With the aid of spinning process adaptations and suitable investigations of the process-structure relationships, precursor fibres with reproducible filament diameters and graphene loads were successfully produced while retaining the filament fineness and filament cross-section and thermomechanically converted to carbon fibres. A meaningful comparability of precursor and carbon fibres of different graph contents is thus possible for the first time. The carbon fibres produced have comparable mechanical properties to nanomodified carbon fibres made of high polymer PAN.

© TUD/ILK

© TUD/ILK

Scientific direction

NameDr.-Ing. Thomas Behnisch

Send encrypted email via the SecureMail portal (for TUD external users only).