Instrumentation for mechanistic in situ investigations of adsorptive heat storage and separation processes

Duration: July 2016 - June 2019

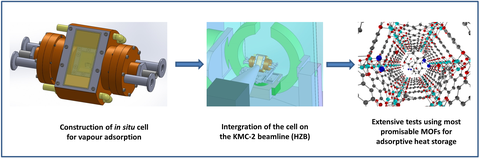

The project is focused on the design, development and commissioning of the automated instrumentation for the parallelized vapour, but also for vapour and gas mixture adsorption and powder X-ray diffraction study on crystalline nanoporous materials. With the high total pore volume as well as the possibility to tune the pore sizes, pore windows and polarity of the inner surface, crystalline nanoporous materials like zeolites and metal-organic frameworks are very promising energy storage materials for adsorption heat pumps and adsorbents for the energy-efficient separation processes. At the same time, there is still a lack of the basic knowledge about the adsorption mechanisms of gas and vapour mixtures in nanoporous crystalline materials, although these are essential for the target efficient application of the latter. Thus, combination of adsorption with powder X-ray diffraction is one of the suitable techniques for performing such investigations. The designed Instrumentation will be commissioned at the KMC-2 beamline (HZB) and will be available for the interested scientists from both material science and adsorption communities investigating materials for energy storage and separation processes.

The following priority points will be addressed within the project:

- Development of the complex sample cell for the in situ adsorption of vapour and gas mixtures in the wide temperature range (298 – 423 K) via synchrotron high resolution powder X-ray diffraction.

- Automation of the system for the user operation at KMC-2 beamline (HZB).

- In situ study of the phase transitions and determination of the preferable adsorption sites in the crystalline nanoporous materials (MOFs and Zeolites) during the adsorption of gas and vapour mixtures.

- Support and instruction of the synchrotron users during their own measurements.