Marko Winkler (birth name Hentschel)

Density and Behaviour of Vibrated Stone Columns in Soft Soils

Introduction

Vibro-replacement using vibrated stone columns is an often applied method for the improvement of soft soils relying on two reasons. On the one hand the stone columns act like vertical load bearing elements with better properties than the surrounding subsoil and on the other hand the subsoil is compacted.

Horizontal strains (radial to the column axis) are caused by the applied vertical loads on the column head increasing the horizontal stresses in the surrounding soil. Since the remaining surface is also subjected to loading additional vertical stresses occure and the soil consolidates. Thus the effective horizontal stresses increase and consequently the resistance regarding radial deformations of the stone columns is also increasing. The load bearing capacity increases due to the larger friction angle, the deformations are reduced caused by the increased moduli and the consolidation is accelerated due to the vertical stone columns acting as a drainage. In general it has to be distinguished between the behaviour of a single column and a group of columns as the column influence each other.

The load bearing and deformation behaviour of vibrated stone columns is influenced by various parameters, which were examined within this study by different lab, field and model tests. One main task of this Diploma thesis included the examination of the compactness of the stone columns which mainly depends on the properties of the surrounding soil and on the properties of the coarse grained stone column material.

In Situ and Laboratory Tests

Tests were carried out at three different sites in order to measure the gravel density in columns produced by the vibro-replacement method:

- Ústí nad Labem (Czech Republic), highway D8 (A17) (A17)

- Kerspleben (village next to Erfurt, Germany), supermarket

- Bernau/Chiemsee (Germany), supermarket

Applied in situ and laboratory tests included:

- Direct measurement of density by replacement method according to German Standard DIN 18125-2 (1999)

- Sieve analysis according to German Standard DIN 18123 (1996) in order to determine the sieve curve

- Experimental determination of the density limits according to German Standard DIN 18126 (1996)

- Grain shape and grain surface

- Dynamic penetration tests according to German Standard DIN 4094-3Ballonverfahren nach DIN 18125-2 (1999) zur Bestimmung der Lagerungsdichte

Results:

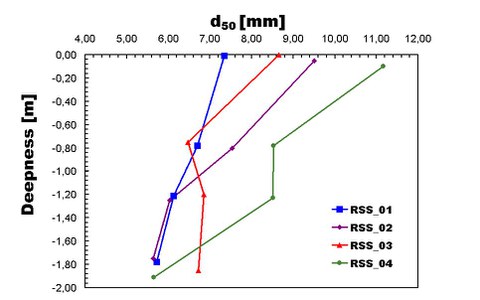

- Decrease of mean grain size d50 with depth and increase of non-uniformity coefficient U=d60/d10 with depth due to abrasion and grain crushing (Figure 2)

- Increase of dry density with depth and decrease of void ratio with depth

- Increase of relative density to a depth of 3 m

- Relative density yields in a range of ID=0,6-0,7 at depth deeper than 3 m

- Larger column diameters in soils with softer properties

- No influence of different vibro-replacement frequencies was detectable

Model Tests

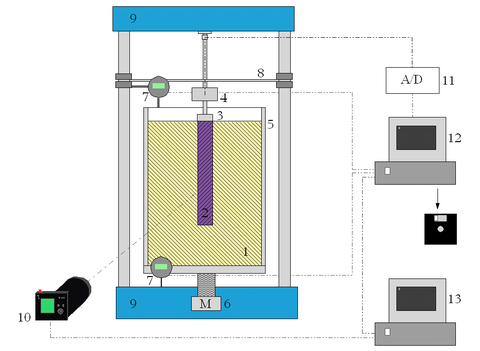

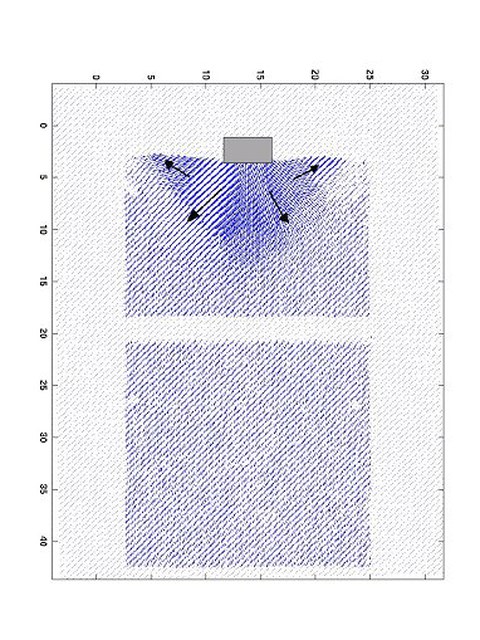

Within the model tests the load bearing behaviour of sand columns depending on the density was tested. The sand columns were surrounded by an artifical sand-polysterol mixture (soiltron). These laboratory tests examined parameters with varying compactness of the sand columns and with differing geometrical distances of the columns. Besides the conventional load-shearing measurements with load cells and dial gauge, the PIV (particle-image-velocimetry) - method was used. The load was put on two varying fundament geometries. Within the first model, model A, both loads were applied due to a tampon which had the same diameter as the head of the sand columns. Within the second model, model B, a loading tampon was used which had the same geometrical size as the whole metal chamber.

Results:

Test series of model A

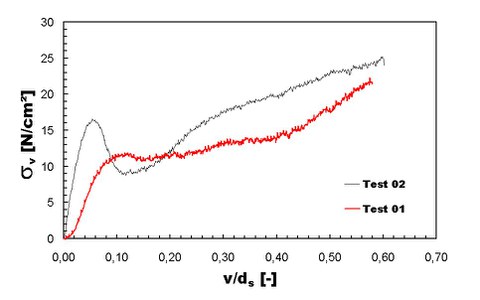

- A stress maximum σv.max was observed at displacements of 5.3% up to 17.0% of the column diameter (see Figure 4).

- σv.max was shown to be up to 65% higher for dense sand columns than for loose sand columns

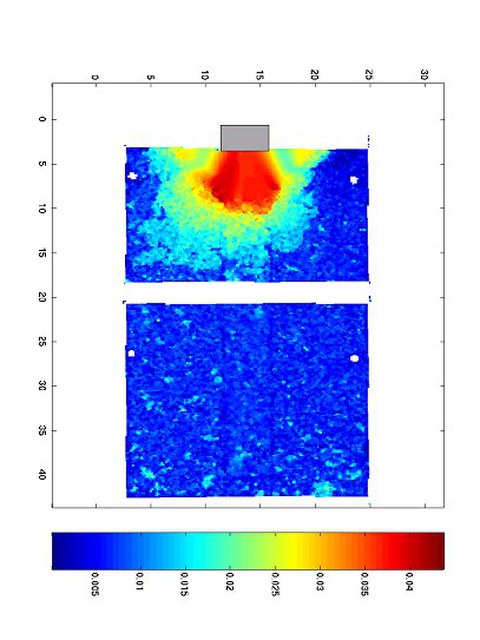

- Formation of a failure mechanism similar to shear failure could be observed (see Fig. 5)

- With increasing displacements a sagment of stresses was observed of values between 91% to 54% of σv.max (see Fig. 4)

- Tests with a small chamber showed no undisturbed formation of failure mechanisms and therefore σv.max was shown to be up to 4.9 times higher.

Test series of model B

- With increasing total displacements (little total displacements) stronger augmentation of vertical stresses at high bulk density

- With increasing total displacements (large total displacements) differences of stresses between loose and dense bulk density were shown to remain constant

Summary and Conclusions

Within the field experiments an increase of soil bulk density was observed which was limited to excavations of not deeper than 3m due to health and safety regulations. From all experiments it could not definitively be concluded whether this observed trend is also valid for deeper layers. In fact, this should be examined further in future projects.

With regard to the model tests it would be interesting to determine the influence of varying sand column and surrounding soil material. Additionally, tests should be carried out to analyse the behaviour of column groups as columns interfere each other.

Project Period:

05/2005 - 08/2005

Supervisor:

© Ulrich van Stipriaan

© Ulrich van Stipriaan

Head of Institute of Geotechnical Engineering

NameUniv.-Prof. Dr.-Ing. habil. Ivo Herle

Head of Chair of Soil Mechanics and Foundation Engineering

Send encrypted email via the SecureMail portal (for TUD external users only).

Chair of Soil Mechanics and Foundation Engineering

Visiting address:

Beyer-Bau (BEY), S 14 George-Bähr-Str. 1

01069 Dresden

Office hours:

on appointment

- Dr. M. Arnold, Technische Universität Dresden

- Dr. J. Boháč, Karls-Universität Prag