Carbon fiber lattice girders

Table of contents

Project data

|

Titel | Title |

Report in the annual report 2023

Hollow core beams with textile lattice reinforcement

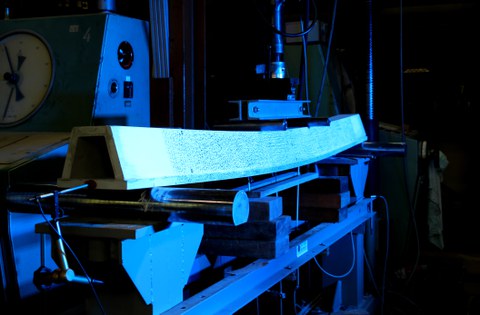

Hollow-core beam reinforced with 3D textile lattice reinforcement subjected to 4-point bending

The aim of the project was to develop 3D textile lattice girder reinforcement element for pre-cast hollow-core slab and wall elements.

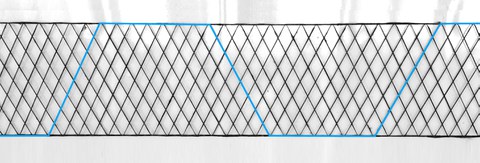

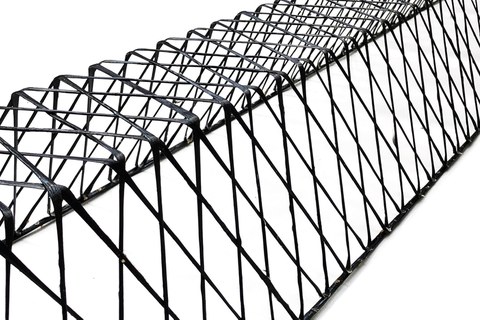

Initially, 2D textile lattice girder reinforcement element was developed. This was the basis for the 3D reinforcement structure. The 2D reinforcement is a continuous textile net-shaped non-ribbed reinforcement structure consisting of several diagonal and staggered carbon fiber rovings. These net-shaped textiles are then processed through a special shaping and fixation method to produce the 3D reinforcement element. The 2D reinforcement is designed to serve as flexural reinforcement when placed horizontally and as shear reinforcement when placed vertically in a beam element. The 3D reinforcement structure serves both as tensile and shear reinforcement in a single configuration.

In the first phase of the project, the focus was on the development of the reinforcement structure. The mechanical properties were then evaluated experimentally in tensile, buckling and yarn pull-out tests to enable an optimization process. The second phase of the project focused on the structural design of the lattice girder and the investigation of the characteristic material behavior of specimens reinforced with the 2D reinforcement structure. This included determining the arrangement and inclination of the diagonally offset rovings. Tensile tests showed that increasing the number of overlapping longitudinal rovings improved the maximum tensile capacity of the beam.

In the final phase of the project, specimens representing sections of a load-bearing structure subjected to bending, such as a ceiling slab, were experimentally analyzed in bending tests. Both 3-point and 4-point bending tests were carried out, resulting in excellent moment resistances. The test results were recalculated and confirmed using numerical simulations of the 3D reinforced element.

Report in the annual report 2022

Textile lattice girder for semi-precast elements

Path of the carbon fibers in the 2D textile lattice girder

In the construction industry, semi-precast concrete elements such as element slabs and walls enable rapid construction progress with low formwork requirements. However, the susceptibility of steel reinforcement to corrosion prevents innovative building structures like resource-saving hollow core construction. In contrast, the use of textile reinforcement materials that are insensitive to corrosion, such as carbon fibers, offers the potential for economical and resource-saving constructions. This research project therefore aims to replace the steel lattice girders previously used in semi-precast floor slabs with three-dimensional lattice girders made of carbon fibers.

For this purpose, the project first defines the requirements for the textile structure of the lattice girders in terms of required diameters, yarn spacing and geometries. In order to ensure walkability during assembly, sufficient compressive stability must be ensured. This is achieved by encasing the mesh girders in concrete already in the precast plant. To characterize the textile-physical properties of the carbon fiber yarns (rovings), tensile and buckling tests are carried out, whereas the bond behavior is characterized by pull-out tests on yarns embedded in concrete in a deflected manner. The characteristic values determined serve as input values for a simulation model for the numerical calculation of the lattice girders in the further course of the project.

In addition, bending tests on two-dimensional textile lattice structures are planned as part of this project. The aim of these tests is to determine the flexural strength of the mesh structures and their composite strength in concrete. The results of the tests will contribute to the validation of the FE model developed.

Based on this, three-dimensionally formed textile lattice girders will be tested. For this purpose, a demonstrator of a floor element with textile lattice girders and cavities is manufactured and its load-bearing capacity is experimentally determined in a bending test. These investigations will serve as the basis for a final comparison of the performance of the new textile reinforced semi-precast elements and conventional steel reinforced concrete semi-precast elements.

Report in the annual report 2021

Carbon fiber lattice girders

Textile latticed girder

Reinforced concrete filigree precast elements (FFT) have established themselves in the construction industry as semi-finished parts for solid walls and slabs in order to achieve rapid construction progress in conjunction with low formwork requirements. Due to the advantageous factory production, a very good and uniform quality of these FFT is achieved, which can only be realized in in-situ concrete with a greater effort. Ideally, the FFT contains already all the reinforcement required for the final state. The use of steel lattice girders represents a proven technology for the production of FFTs that is well established on the market. However, the corrosion susceptibility of reinforcing steel as well as the high transport costs prevent innovative construction designs in resource-saving sandwich or hollow core construction methods.

Compared to conventional steel reinforcement, the use of textile reinforcement materials that are insensitive to corrosion offers the potential for economical and resource-saving constructions. By completely replacing steel reinforcement by carbon fiber reinforcement, it is possible, for example, to make semi-precast slabs thinner and with cavities – while at the same time maintaining a very high load-bearing capacity. This increases e.g. the possibilities of use for installations.

This project, therefore, aims to replace the steel lattice girders previously used in semi-finished slabs with three-dimensional lattice girders made of carbon fibers. In this context, the lattice girders must both provide the reinforcement required for the use and handling of the new type of semi-precast slabs and form part of the flexural reinforcement of the slab. Novel shear-resistant elements are therefore required to achieve the compressive stability necessary to ensure walkability during erection. The aim of the project is thus the development of textile 3D lattice girders made of carbon fibers as well as their manufacturing technology for large-scale industrial use in novel semi-finished slabs with integrated, large-volume cavities.