Woodtrusion (Elasticity, Compression and Springback of Densified Wood)

| Head of Research : | Prof. Dr.-Ing. Peer Haller |

|

Research Assistant: |

Siavash Namari, M.Sc. |

| Participating Research Centers: | Institut für Textilmaschinen und Textile Hochleistungswerkstofftechnik Leichtbau-Systemtechnologien KORROPOL GmbH STM Montage GmbH (Niemeier Fahrzeugwerke GmbH) |

| Processing Period: | 01.05.2018 - 01.10.2020 |

| Funding Association: | STFI Sächsischen Textilforschungsinstitut e.V. (FNR) |

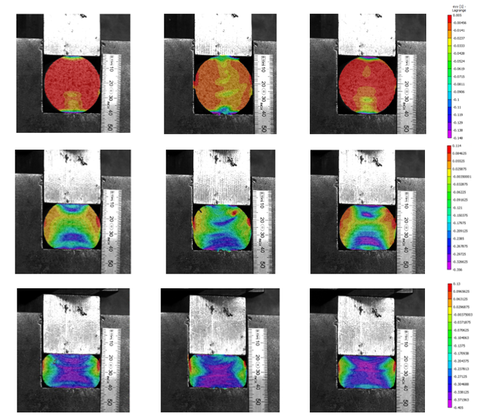

The Woodtrusion project (lead by Sächsisches Textilforschungsinstitut e. V. (STFI)) is an innovative initiative aimed at transforming low-quality thin wood into high-quality structural wood, specifically designed for tubular profiles. This approach utilizes a unique compression process that applies both heat and pressure, significantly enhancing the mechanical properties of wood, such as strength and durability. The goal is to produce wood tubes capable of withstanding structural demands by optimizing the material properties of cellulose fibers within the wood. Key objectives for the Chair of Timber Engineering in the Woodtrusion project include testing and analyzing the densified wood's physical and mechanical properties, such as elasticity, compressive strength, swelling and spring-back forces. Additionally, mechanical models and finite element analysis are being employed to simulate and predict the behavior of the compressed wood under various conditions.