Ultrasound

Motivation

Liquid metals are of outstanding importance for a variety of industrial processes, for instance in continuous steel casting or crystal pulling in the photovoltaics or semiconductor industry. They have in common that by influencing the flow pattern of the liquid metal, the quality of the resulting product as well as the energy efficiency of the process can be improved. An elegant and contactless way of controlling the flow in a metal melt is the application of a time-varying magnetic field. Its interaction with electrically conductive fluids is investigated in the field of Magnetohydrodynamics (MHD) by the means of numerical simulations and model experiments.

Requirements

In order to understand the flow phenomena that occur from the interaction of conductive fluids and magnetic fields in experiments, a spatially and temporally resolved flow instrumentation is needed. It must be able to capture the comprehensive parts of the flow field in multiple planes simultaneously.

Why Ultrasound?

Good electrical conductors are opaque, so no optical flow measuring techniques can be used with liquid metals. An alternative method is the well established and widely used ultrasound Doppler velocimetry (UDV). It allows a non-invasive flow measurement in various fluids as sewage, yogurt, chocolate, as well as in liquid metals.

The Measurement System

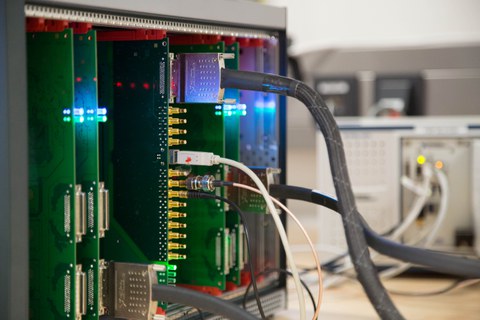

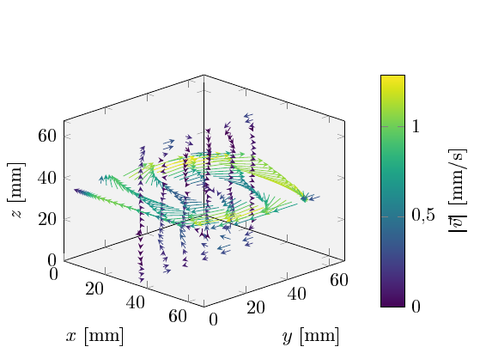

The MST developed a modular and flexible measurement system for flow instrumentation the phased array ultrasound Doppler velocimeter (PAUDV, see Figure 1). It uses custom arrays of up to 256 ultrasound transducers that emit short busts and detect the echos reflected from within the fluid. Through precise timing of the emissions in the nanosecond range an electronic control of the US beam shape is performed by means of the phased-array principle. This allows to achive a spatial resolution of >1 mm in the measurement field. The signal processing is performed on an field programmable gate array (FPGA), which calculates velocities from digitized echo signals. Subsequently the flow is visualized with a frame rate of >30 Hz.

Results

The UADV system allowed investigating flow phenomena in various experiments: The transition of flow behavior between laminar and turbulent flows in cubic containers, which is relevant for basic research in MHD, was visualized. Furthermore the influence of magnetic fields to the liquid metal flow in a model of the continuous steel casting process and a model of crystal growth for the photovoltaics industry could be studied.

In this field we have the following projects: