Research at the chair of Ultra-precision surface machining

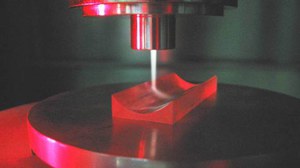

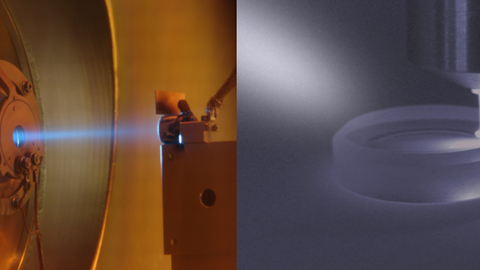

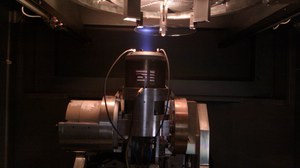

The Chair focuses on fundamental research into the interaction mechanisms of chemically reactive atmospheric pressure plasma jets and low-energy ion beams with surfaces. This knowledge is used to develop deterministic processing technologies for ultra-precise shaping of optical and semiconductor surfaces up to industrial production chains. The main field of application for the technologies is the production of complex surface shapes such as aspheres and free-form surfaces for ultra-precision optics, which have to be manufactured with production tolerances of just a few nanometres.

© Arnold

© Arnold

Ultra-precision surface machining with ions and plasmas

The UPB Chair conducts fundamental research into the mechanisms of interaction between chemically reactive atmospheric pressure plasma jets and low-energy ion beams with surfaces and develops processing technologies for the ultra-precise shaping of surfaces through to production chains suitable for industrial use. The main field of application of the technologies is the production of complex surface shapes such as aspheres and free-form surfaces for ultra-precision optics, which must be produced with manufacturing tolerances of a few nanometers. These requirements apply to the long-wave form as well as the medium-wave structure range and micro-roughness. In order to meet these requirements, beam-based processing tools (plasma jet sources, ion beam sources) are also being further developed. The shaping and correction of surfaces requires precise measurement technology to determine shape and roughness. The working group has a comprehensive range of state-of-the-art measuring systems at its disposal for this purpose.

These research topics are addressed by the Chair at the Leibniz Institute for Surface Modification (IOM) in Leipzig.

More on the topic: Core research areas