Research

Research in the field of structural durability focuses both on calculated and experimental life cycle verification.

Calculated verifications are meant to produce expertise on novel materials and methods of calculation, however, they also provide scientific input for the improvement and expansion of existing regulations. During the experimental life cycle verification, methods for the materials and component testing are being developed and tested, in order to face specific fatigue phenomena with appropriate testing methods.

© AG Betriebsfestigkeit

© AG Betriebsfestigkeit

Research

Research at the Structural Durability Group is traditionally characterised by a combination of theoretical and experimental investigations of dynamic fatigue strength and structural durability, as well as the experimental solid mechanics.

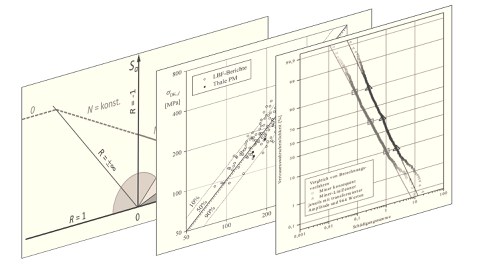

Calculated Life Cycle Verification

Work on the mathematical life cycle verification deals with developments and improvements of typical concepts of structural durability, such as the local notch strain concept, the nominal stress concept and the notch stress concept. Recent works furthermore shed light on fracture-mechanical aspects of dynamic fatigue strength.

In addition to research on novel materials, existing findings should be made available for further conclusions. Comparative studies of existing data thus represent an important foundation for the improvement of many experience-based methods and can be made available to the respective engineer in the form of sets of rules.

Experimental Life Cycle Verification

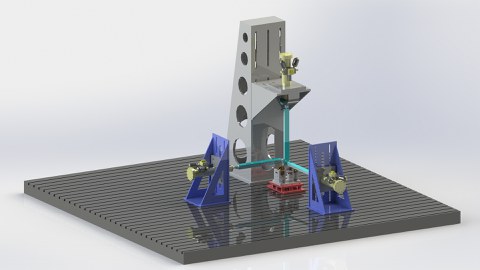

Experimental data are the foundation of each empirical model. In many cases, standardised test methods or commercial solutions can serve for the development of theoretical methods of dynamic fatigue strength and structural durability. In contrast, it is often the case that –during experimental life cycle verification – some questions emerge requiring special research. Typical requirements in the field of structural durability are:

- illustration of realistic load-time functions in operational load simulation;

- rapid commissioning of test benches;

- component testing with nonlinear or active component behaviour;

- reduction of test duration;

- continuous quality assurance during the experimental procedure.