Experimental Characterization and Modeling

Modeling inelastic material behavior is a key aspect of the professorship. For solving engineering problems the phenomenological modeling within continuum mechanics is productive and has been applied successfully. The specific properties of a material probe to act on thermal, magnetic, electric and mechanical loads are considered by constitutive equations which influence the structural behavior. The material parameters have to be identified with the aid of an experimental characterization.

Experimental Characterization

First step of material modeling reads the task to find out to which material family a material probe belongs, either solids, fluids or yield stress fluids. In few of describing the material behavior it is also useful to classify the material behavior in one of the material classes elasticity, plasticity, viscoelasticity or viscoplasticity. Classification criteria are the equilibrium relation and rate-dependent effects. In order to classify material behavior characterization experiments are performed. Rate-dependent effects can be properly studied by monotonic experiments with different strain rates and relaxation experiments. Additionally, the investigation of directional properties are important for anisotropic materials.

Experimental characterization by monotonic experiments with constant strain rate (left), one step relaxation experiment (middle) multi step relaxation experiment (right)

The experimental investigation of material behavior is done at the professorship with concerted measurement equipment. The influence of local inhomogeneous effects on the global material response makes optical measurement technique necessary.

Continuum Material Modeling

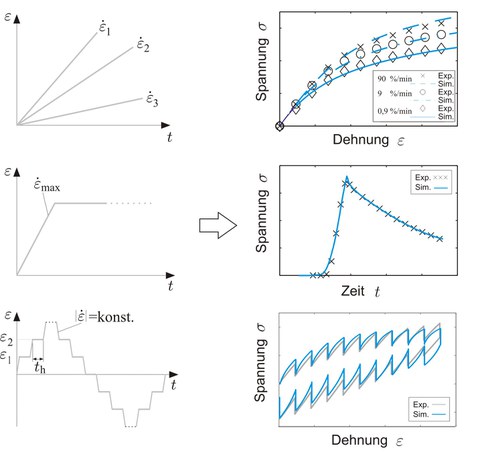

Subsequent to the experimental characterization applies the modeling process. A two step phenomenological modeling strategy on the basis of characterization experiments has been developed as powerful method. In the first step rheological models are connected to a one-dimensional material model which is able to reproduce all the measured material phenomena. Afterwards, three dimensional constitutive equations are derived with the aid of a thermodynamical consistent generalization considering directional properties. Modeling process closes with material parameters identification.

Continuum material modeling based on results for experimental characterization