Facilities

The research performed by the Chair of Mechanics of Materials and Failure Analysis focusses primarily on characterising the deformation behaviour and the damage mechanisms associated with cyclic mechanical stress. The test systems used for this research include:

- Ultrasonic fatigue testing systems (test frequencies of approx. 20,000 Hertz)

- Resonant frequency testing systems (max. test force 50 kN, test frequencies of 100-250 Hertz and 1000 Hertz)

- Servohydraulic test systems (various test forces, test frequencies of up to max. 50 Hz)

- Low load testing system (2kN, test frequency of up to max. 140 Hertz)

- Cavitation test system

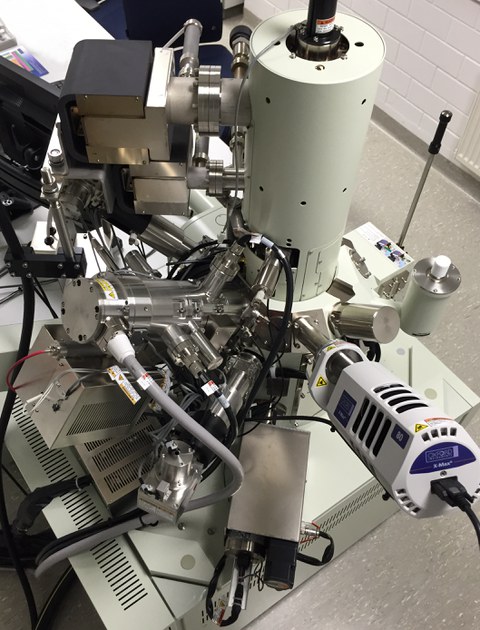

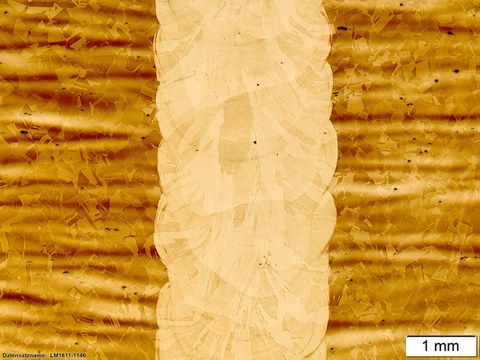

The PhD students and student assistants working at the Chair closely collaborate with the team from the Fraunhofer Institute for Material and Beam Technology’s Department of Materials Characterisation and Testing. As part of this collaboration, the departments’ researchers are also able to make use of the institute’s expertise in electron microscopy. The institute has a modern metallographic lab as well as a scanning and transmission electron microscope with X-ray microanalysis systems for microstructure characterisations and fractographic investigations. In addition to standard topographic information, its ultra-high resolution field emission SEM detectors are particularly suited to generating and combining orientation and materials contrast composition images.

The institute’s sample preparation technology (such as the Cross Section Polisher) also makes it possible to create the samples required for ECCI, the use of which in particular makes it possible to generate high quality and high resolution images of dislocation structures. The institute’s TEM features two camera systems and a precision-controlled sample table which make it possible to obtain highly effective and accurate images of lattice defects (dislocations and grain boundaries) at the same time as identifying the local crystallographic orientation or differences in orientation. Furthermore, the institute has an SEM with Focused Ion Beam Technology for systematic TEM foil specimen removal.