Quality assurance

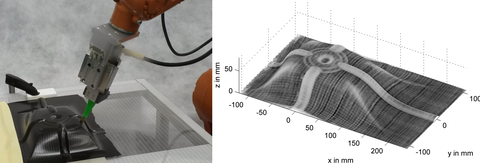

Eddy current testing of a complex CFK component (left) and eddy current image (right)

The construction and specific enhancement of customized measuring systems for online quality assurance and parameter registration of textile production and manufacturing processes is a focus of ITM activities. Methods for online quality assurance are based on non-damaging and preferably contactless registration of material properties (e.g. surface structure, area weight, error density) and process parameters (e.g. thread tensile force, oscillations, power consumption, temperature distribution), which are usually compares to predefined desired values. They allow a fully automated, cost-efficient and low-maintenance control over the manufacturing process, by which errors are detected early and follow-up costs are minimized. The ITM commands the relevant know-how and measuring technology is available for the recording of any material and process parameters along the textile value chain. Such systems are used specifically to analyze individual process steps and derive industry-relevant improvement potential like higher efficiency, improved product quality or lower energy consumption.

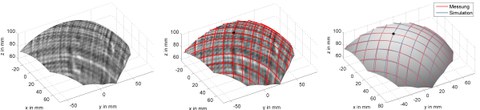

The ITM also co-operates with experts from research and industry to develop tailor-made quality assurance systems, especially for the area of technical textiles and fiber-reinforced composites. As an example, the draping process of carbon fiber multiaxial non-crimp fabrics is examined by means of high-frequency eddy current tests. These make the correct thread course and absence of errors verifiable in the deeper layers of carbon fiber preforms. A fully automatic assessment of the results allows a recording of the actual thread course in 3D preforms, and a comparison for the ideal thread course, e.g. from draping

Eddy current measuring of a draped non-crimp fabric (left), automatic determination of thread courses (center) and comparison to simulation

Contact person:

© Mirko Krziwon

© Mirko Krziwon

Mr Dr.-Ing. Hung Le Xuan

Research Group Leader Sensor, Measurement and Actuator Technology

Send encrypted email via the SecureMail portal (for TUD external users only).

Visitor Address:

George-Bähr-Straße 3c, Zeuner-Bau, Room 120B

01069 Dresden

Deutschland

© Mirko Krziwon

© Mirko Krziwon

Mr Dr.-Ing. Johannes Mersch

Research Group Leader Sensor, Measurement and Actuator Technology

Send encrypted email via the SecureMail portal (for TUD external users only).

Visiting address:

George-Bähr-Straße 3c, Zeuner-Bau, Room 120B

01069 Dresden