Structure and process simulation

Structure and process simulation at the ITM

The modeling and simulation of textile production processes and the mechanical and physical properties of the yarns, yarn constructions and various textile structure like woven, non-woven, non-crimp, or braided materials is becoming increasingly important in research and industrial practice. Accompanying simulation significantly shortens development time, as prototype construction and related analyses on the actual, real structure are reduced. The ITM strongly position with a variety of developed models based on the Finite Element method. Textile Structures and production sequences along the entire process chain are modeled and simulated, and a wide range of textile simulations for construction, medical and reinforcement textiles for composites are conducted.

Modeling and simulation of textile processes and structures

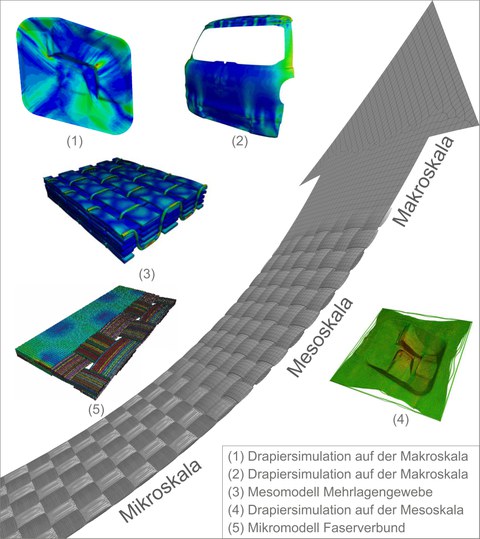

The construction of technical reinforcement textiles starts with the high-performance filament, which is used to create reinforcement yarns, which become complex textile structures. The structural-mechanical analysis and dimensioning are performed according to need on various levels of abstraction. Multi-scale modeling and simulation are used at the ITM to specifically research textile high-performance materials for a number of application fields, and to enhance textile semi-finished products and production methods.

The aim of modeling and simulating textile processes and structures is to create simulation solutions for predictions of:

- material properties of yarns and textile fabrics (woven, mesh fabrics, non-woven fabrics, non-crimp fabrics, and braids),

- influencing factors of processing methods and finishing agents on material properties,

- influences of construction parameters on the material properties (structure-property relationships), and

- functional properties like mechanics, draping behavior, and permeability.

Furthermore, the ITM supports the preforming of reinforcement textiles for composites or in the development of construction and medical textiles with the following research efforts:

- development and validation of material and simulation models for the textile simulation on micro, meso and macro levels,

- realization of structural simulations for the determination of functional properties,

- analysis of production processes by simulated weaving, braiding, deformation or draping,

- enhancement of quality assurance methods, e.g. high-frequency eddy current measuring,

- development and construction of unique test rigs for the determination of material properties and laws, and for research into preforming with different-complexity geometries and active process control.

The ITM uses modern computing technology and extensive modeling and simulation software (LS-DYNA, ANSYS Composite PrepPost, SolidWorks, MATLAB, GeoDict, etc.).

Contact person:

© Mirko Krziwon

© Mirko Krziwon

Mr Dr. Thomas Gereke

Research Group Leader Structure & Process Simulation

Send encrypted email via the SecureMail portal (for TUD external users only).

Visitor Address:

George-Bähr-Straße 3c, Zeuner-Bau, Room 132

01069 Dresden

Deutschland