Separation and joining technologies

CNC sewing technology and sewing robot in the process chain for assembly-technical preform production

The joining methods like sewing, welding and gluing, connection processes and their parameters, the development and construction of machines and the application of these techniques for the textile assembly of technical textiles, home and decor textiles, or functional garments with special seam properties are the subject of this department. Especially the assembly processes for technical textiles and preforms for fiber-reinforced plastic composites require application-adapted assembly techniques and technologies with integrated sensors and actuators for reproducible completion of the seams.

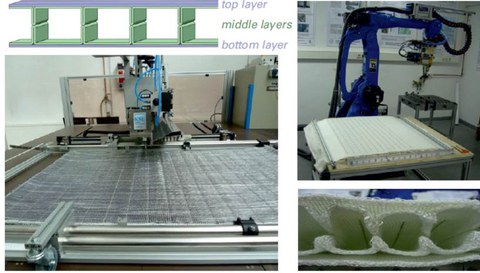

Sewing is a textile-typical joining method and universally suitable for a wide range of flexible materials. 3D sewing technologies are one of the main areas of interest at the ITM, as they have potential for the production of technical textiles, e.g. in car headrests and seats, and for complex preforms made from high-performance fibers. Spatial sewing is based on the use of unilaterally working sewing heads guided along a 3D molded body (covered by the cuttings) with product- or preform-similar geometry by a jointed arm robot.

CNC sewing in 2D is used for the assembly-technical realization of plane and curved textile spacer structures, to fixate multilayer preform architectures, and to integrate electronics modules and inserts.

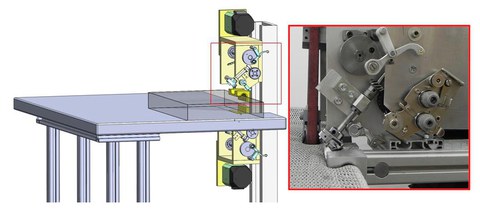

Furthermore, new sewing technologies are being developed at the ITM, and new machine concepts and sewing tools are realized in close co-operation with industrial partners.

Technology concept and realization for the three-dimensional edge treatments of spacer fabrics, machine realization in co-operation with Pfeil Nähmaschinen GmbH

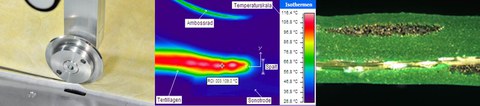

Textile welding technologies rely on heating the thermoplastic material or activating the thermoplastic adhesives by means of ultrasound, electric high-frequency fields or hot air. The substance-to-substance bond between the textile parts can create specific seam properties for applications in membrane construction, in healthcare and nursing, and in work safety. This requires a process and characteristics design adapted to the material and desired application. The focus is on process examination by means of metrological recording of process and machine parameters in relation to the material properties and resulting seam characteristics. Quality control and process optimization allow a targeted adaptation of product properties during joining.

Process examinations in the joining zone during ultrasound welding, and seam cross-section

The ITM’s assembly-technical laboratories are equipped with an extensive array of machinery for their research.