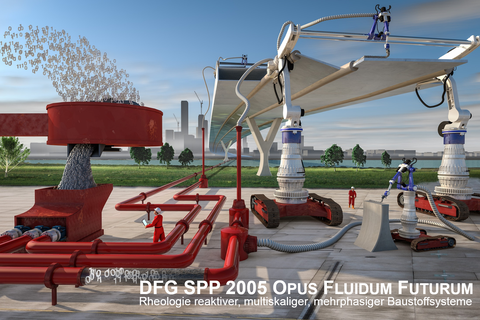

Priority Program 2005 - "Opus Fluidum Futurum - Rheology of reactive, multiscale, multiphase construction materials”

Scientific objectives

The scientific objective is to provide theoretical and experimental foundations for rheology-based design of building processes and for the development of new, sustainable building materials and breakthrough processing technologies. Specifically, the priority programme will pursue the following goals:

- Investigate and analyse the interactions of reactive (hydrating) particles at the micro level including quantification of influences (morphology, chemistry, temperature, time, etc.) and modelling of particle interactions.

- Development of strategies and concepts for the description of deformation and flow processes of fresh concrete on the basis of microscale processes and taking into account mesoscopic processes (segregation, deaeration, fibre distribution, etc.)

- Analysis and penetration of the decisive processing procedures of fresh concrete (conveying, placing, compacting, smoothing, etc.) using scientific tools and methods of rheology

- Elaboration of measurement methods for recording the behaviour of fresh concrete on different observation levels and for different stress scenarios

- Development of constitutive material laws for fresh concrete to simulate the phases and processes of processing.

To achieve these objectives, the programme is divided into three modules.

Module I: Particle interactions as a basis for the rheology of binder suspensions

Module II: Flow and deformation behaviour of fresh concrete

Module III: Material laws and methods for describing and influencing technological processes

Thematic delimitation of the priority programme

Module I

In the first funding period, work was carried out in particular on force-particle distance-effect relationships, taking into account the binder composition and the addition of organic concrete admixtures. A Portland cement, a blast-furnace cement and two different superplasticisers served as reference materials. The focus of the second funding phase will be on extending the considerations to concrete compositions with sustainable admixtures. A limestone powder and a calcined clay serve as reference materials together with the Portland cement and superplasticisers from the first funding period. Other binder systems such as geopolymers or alternative cements (for example calcium aluminate cements or inorganic phosphate cements) are not considered in the priority programme. The use of other admixtures is additionally possible depending on the problem. The development of additives and admixtures is not one of the objectives of the priority programme.

Module II

In the second module, methods for transferring particle-based interactions to the macroscopic flow and processing behaviour of building material suspensions have been developed so far. In addition to investigations on homogeneous suspensions, shear-induced segregation processes in particular were also investigated and made model-theoretically ascertainable. Based on these findings, the analytical and numerical modelling of concrete flow behaviour is to be expanded in the second funding period. The development of fundamentally new numerical algorithms is not the goal of the priority programme; rather, the focus should be on the most accurate possible reproduction or prediction of the material behaviour in the context of the respective stresses and framework conditions. In addition, research work in the second funding phase should concentrate in particular on special concretes such as low-water concretes, concretes for additive manufacturing processes, fibre concretes and concretes with recycled aggregate.

Module III

In the first phase of the priority programme, specific construction technology processes, such as filling a formwork with concrete or pumping concrete, were modelled analytically and numerically. Initial considerations were made with regard to novel installation technologies and the associated concretes, such as 3D printing with concrete. In the technology-related projects, a close link to the material laws to be developed in Module I and II as well as a physically based description of the process was pursued.

In the second funding period, the rheological behaviour of the finished suspension and not the technology for producing this suspension should still be in the foreground when selecting the processes under consideration. With regard to work at the building materials technology/machine interface, it is also expected that the rheological properties of the suspension will be clearly at the forefront of research. Additive manufacturing processes are expected to play a prominent role. The object of the programme is not the optimisation/improvement of individual technological processes, but rather the creation of the scientific basis on which such optimisation can be carried out within the framework of industry-related projects.