Influence of loading speed and frequency on fatigue resistance

Table of contents

Project data

| Titel | Title Einfluss der Beanspruchungsgeschwindigkeit und der Belastungsfrequenz auf den Ermüdungswiderstand von Beton (EBBE-Beton) | Influence of loading velocity and loading frequency on the fatigue resistance of concrete (EBBE-Beton) Förderer | Funding Deutsche Forschungsgemeinschaft (DFG) Zeitraum | Period 08/2020 – 12/2024 Projektleiter | Project manager Prof. Dr.-Ing. Steffen Marx Team | Team Raúl Enrique Beltrán Gutiérrez, M.Sc. Doreen Sonntag (Versuchsdurchführung | Test execution), Heiko Wachtel (Messtechnik | Measurement technology) |

Report from the year book 2023

Playing with a concrete ball

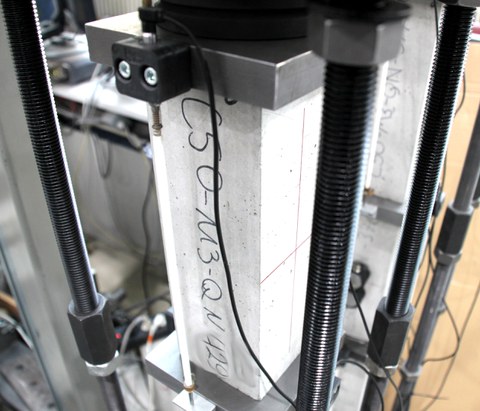

Specimen in a concrete creep test set-up

Imagine a ball that on the one hand behaves like a hacky sack – without bouncing, but stretching very slowly but continuously – and on the other hand bounces incessantly like a space ball, as if it had a life of its own. There is a group of materials, including concrete, that exhibits this peculiar behavior. This means that the deformation behavior changes depending on the load conditions. The evolution of the deformation of concrete depends on the time scale in which the loading process takes place. The rate of loading therefore determines the deformation behavior. If the load is increased very slowly with, e.g.

10–3 N/mm²s at most, or remains almost constant, the deformation appears to be significantly influenced by concrete creep. On the other hand, when concrete is loaded very rapidly, its stiffness appears to increase and its deformation pattern changes significantly.

The investigation of these properties is particularly important for concrete structures that are exposed to fast cyclic loads, such as wind turbines or bridges. Both in these structures and in laboratory tests, the speed at which load cycles occur has an influence on the fatigue strength of the material or structure. To highlight these differences and to investigate the changes in the mechanical properties of concrete exposed to extreme loading rates, in the frame of the EBBE-Beton project, we carried out creep tests and compression tests at very high loading rates up to approximately 106 N/mm²s. Based on the experimental data, the influence of the loading rate on the development of fatigue damage is taken into account and models will be further developed.

The use of these models will improve the previously limited applicability of results from fatigue tests with high loading rates in the laboratory to real component situations with lower loading rates. Even Haaland or Messi would not dare to play with our quirky concrete ball without this knowledge and appropriate models.

Report from the year book 2021

Fast or slow to concrete fatigue?

Concrete specimen under cyclic loading

Concrete bridges are subjected to a large number of loading cycles caused by cars, trucks or trains during their service life. As a result, the concrete fatigues at the areas subjected to high stresses. In recent years, knowledge gaps, as well as discrepancies between the fatigue behaviour observed in the laboratory and the actual fatigue behaviour of concrete structures, have been discovered. For example, fatigue strengths calculated based on laboratory tests have a lower value than the actual fatigue strengths estimated in the real structures. The high cyclic loading frequency and the resulting internal temperature increase during the laboratory tests apparently cause additional damage to the concrete specimens.

Currently, concrete specimens are tested under laboratory conditions in fatigue tests at the highest possible cyclic loading rate until fatigue is reached. This is done to minimize cost and testing time. For example, to simulate the number of cyclic loads on a specimen that a bridge will be subjected to over 10 years, it would take about 23 days under normal laboratory conditions with a loading frequency of fp = 5 Hz. Moreover, one would need several many specimens to validate the results of the tests. Therefore, it seems logical to increase the cyclic loading rate. Only if the testing times for the fatigue tests could be shortened without compromising the quality of the results, it will be possible to realistically simulate the fatigue damage evolution over the expected lifetime of the bridge in the laboratory.

As part of this research project, numerous tests will be conducted at different cyclic loading rates and temperature conditions to relate the fatigue strength of concrete to the above factors. The experimental data will later be used to develop models that take into account the influence of the loading rate as well as the temperature increase on the development of fatigue damage. With the help of the models developed in this research project, the previously insufficient applicability of laboratory results from fatigue tests to real component situations will be made possible.