Influence of load-induced temperature fields on the fatigue of UHPC

Table of contents

Project data

| Titel | Title Einfluss lastinduzierter Temperaturfelder auf das Ermüdungsverhalten von UHPC bei Druckschwellbelastung | Influence of load-induced temperature fields on the fatigue behaviour of UHPC subjected to high frequency compression loading Förderer | Funding Deutsche Forschungsgemeinschaft (DFG) / SPP 2020 Zeitraum | Period 09/2017 – 03/2022 Leiterin | Project manager Dr.-Ing. Silke Scheerer Bearbeiter | Contributor Dipl.-Ing. Melchior Deutscher Projektpartner | Project partner Institut für Massivbau, TU Darmstadt |

Report in the annual report 2021

Temperature changes load high

Sealed HPC cylinder during heating for static compression test

With increasing concrete compressive strength, slimmer structures such as long-span bridges are being realised. In addition to high static forces, these structures also experience a high number of load changes due to vibration. Besides the compressive strength, the fatigue behaviour also becomes more relevant. In conventional reinforced concrete, the steel properties are usually decisive for the fatigue design. This is due to the significantly higher material strength of steel and lower cross-sectional areas that result in higher stresses. Ultra-high performance concretes (UHPC), however, approach the strength of steel, which also shifts the cross-sectional area ratio of the two composite materials and makes concrete fatigue more decisive.

These aspects are currently being addressed by the Priority Programme SPP 2020 to investigate the fatigue behaviour of (ultra-)high strength concretes. When carrying out pressure swell tests, which are used to characterise the fatigue strength of concrete, the concrete heats up at higher loading frequencies. In the project presented here, this heating is systematically investigated to define decisive influencing variables and to be able to take the increased temperature influence into account in the evaluation of test results.

The experimental investigations showed that the heating up is mainly dependent on the stress play. Unlike the fatigue strength, which is more dependent on the maximum stress level, here this influence is equal to the influence of the minimum stress level. Test specimens that heat up strongly also fail earlier than would be expected according to fib Model Code 2010 approaches. Investigations on the static compressive strength of UHPC in the range of the measured temperature up to 90 °C showed a reduction of up to 15% of the uniaxial compressive strength. This reduction takes place continuously during the pressure swell tests with increasing temperature. With constant absolute force play, the related stress thus changes, which causes premature failure.

Within this project, an approach was developed with which the strength reduction is taken into account mathematically as a function of the maximum temperature and the stress play. The pressure swell tests can thus be carried out up to 20 Hz without additional effort and the heating up can be taken into account subsequently.

Report in the annual report 2020

Increase the pressure

Investigation of different concrete strength; left: UHPC, center: HPC and right: NC

Materials research is trying to respond to the quest for slimmer, larger and more material-efficient buildings and structures. In concrete construction, this is implemented by increasing the compressive strength. The slenderness of structures increasingly implies strong dynamic and cyclic loading. Comprehensive knowledge of fatigue behaviour is therefore of great importance for the use of ultra-high performance concretes (UHPC) and high-performance concretes (HPC) in construction praxis. To fulfill previous knowledge gaps, the SPP 2020 project “Influence of load-induced temperature fields on the fatigue behaviour of UHPC subjected to high-frequency compression loading” has been dealing with these aspects since 2017. Knowledge about the fatigue behaviour as well as the generation of Wöhler lines for the standardisation of concrete is generally gained by using pressure swell tests on cylinders. High frequencies and high strengths lead to concrete heating, which influences the achievable number of load cycles. In the SPP project, a systematic investigation of this phenomenon is being carried out. The aim is to identify and quantify the causes and effects of heating.

With the finishing of the experimental main part of the project, the parameters upper stress, lower stress, frequency, maximum grain size as well as concrete strength were considered. The heating per load cycle was influenced by all parameters except frequency. Increasing stress cycles increase the energy introduced, a lower maximum grain size also leads to an increase due to higher internal friction potentials as well as an increase in the concrete strength, which is associated with denser storage of the components of the concrete. The frequency influences the heating process via the repetition of the energy input. The higher the frequency, the more heat is introduced per unit of time while the cooling does not increase evenly over the surface. This leads to an increase in the heating rate.

The compressive strength of high performance and ultra-high performance concrete is degradative affected by temperature. Due to the increasing temperature, an unwanted increase of the related load cycles is generated, which is a main cause for the supposed early failure. The experimental investigation of the temperature-dependent strength should enable the temperature influence to be calculated out with the knowledge of the heating processes.

Report in the annual report 2019

UHPC – heating through fatigue

Specimen for test under cyclic loading with three thermocouples distributed over the sample’s height

The increasing requirements for structures need high-performance materials that allow ever slimmer and more efficient structures. This has led to the development of ultra-high performance concretes (UHPC) in construction. When used as machinery and wind turbine foundations, the concrete is subjected to frequently recurring, large loads. For this purpose, planning requires sufficient knowledge of fatigue behaviour. The existing knowledge gaps in this subject area are addressed by the priority program SPP 2020.

Specimen during the test with insulation to prevent temperature release

In previous fatigue investigations on high-performance concretes, heating caused by cyclic loading was detected. In the subproject “Load induced temperature fields at UHPC” a systematic investigation of this phenomenon is carried out. The aim is to identify and quantify the causes and effects of heating. Accompanying the experimental investigations in Dresden, a material model is being developed at the TU Darmstadt which describes the damage behaviour of UHPC under cyclic loading. In the course of the main cyclic tests, the parameters frequency, maximum stress level and grain size have been investigated. A significant effect on the heating of the UHPC could be determined for all mentioned parameters. Heating was measured in all tests carried out. However, the maximum temperatures reached and the heating rate were very different. The load frequency mainly has an influence on the maximum value of the achieved temperature. If the load frequency increases, higher temperatures are reached. The parameters maximum stress level and maximum grain size mainly influence the speed of the temperature rise. The temperature curves become steeper with increasing maximum stress level. At the same time, however, the increase in maximum stress level also causes earlier fatigue failure, which is why the maximum temperature is not necessarily reached at maximum stress level. When using different grain sizes as aggregates, it was found that similar maximum temperatures are reached, but finer aggregates lead to a faster temperature increase. Thus the grain size also has an influence on the achievable number of load cycles due to the heating ratio.

Along with the further planned experiments on specimen size and material strength, the heating phenomenon can be described comprehensively.

Report in the annual report 2018

UHPC under cyclic loading

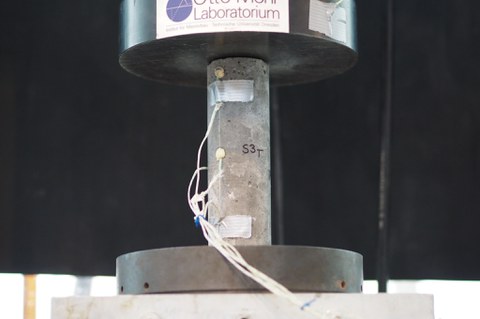

Compression test in the triaxial test facility of Otto Mohr Laboratory

In the future, ultra-high-performance concrete (UHPC) will make it possible to build even larger and leaner structures than those that are feasible today. In addition to static loads, these type of structures is subjected to cyclic loading. Fatigue behaviour will, therefore, have a growing influence on the concrete construction industry in the future. The DFG Priority Programme SPP 2020 investigates the development of damage in a structure from various points of view, and it describes such behaviour using numerical methods. The research is devoted to filling the gaps between the existing knowledge and the actual damage behaviour of UHPC under cyclic loading.

The subproject “Load-induced increase in temperature at UHPC” deals with the phenomenon of UHPC heating under cyclic loading. This has been observed in previous investigations on high-performance concretes and has been recognised as a non-negligible influencing factor on the damage behaviour. The aim of the project is to systematically investigate and quantify the causes and effects of material warming. At the TU Darmstadt, a material model is developed on the basis of the results of the tests, which describes the damage behaviour under fatigue load.

High-speed recording of a standard cylinder made of ultra-high-strength concrete during compression failure

In the first work package, the selected two high-performance concretes were tested for their basic static values such as tensile and compressive strength, stiffness, multi-axial material behaviour, etc. The values are used to describe a material model under static loading, which is then adapted for the fatigue behaviour under cyclic loading. In order to determine the minimum concrete age for the cyclic tests, an additional strength development was established. The compressive strength shows no significant change after 90 days and is approx. 180 N/mm². Thus, experiments over a longer period of time are possible.

Finally, in the first work package, preliminary tests were carried out in which the selected measurement methods and test configurations were tested. Significant heating of up to 35 K could be measured with temperature sensors in and on the surface of the test specimen. In the next step, the main tests will be carried out, in which the influencing factors of high stress, loading speed, maximum grain size and specimen size will be investigated.

Report in the yearbook 2017

Load-induced increase of temperature in UHPC

Specimen for test under cyclic loading with three thermocouples distributed over the sample’s height

The development of the construction industry moves towards resource-saving and filigree constructions. Ultra-high performance concrete (UHPC) was developed to reach a higher efficiency of this material. As a result, the structures will be leaner and lighter in the future. However, due to a reduction of dead weight through the optimized use of materials, structures are more susceptible to induced vibrations. This is particularly important in the area of cyclically stressed structures, such as long-span bridges and wind turbines, which are exposed to very high number of load cycles. In particular, a thorough understanding of the fatigue behaviour of UHPC is required. The Priority Programme SPP 2020, funded by DFG, addresses this topic. Within the SPP, the aim is to explore the material degradation of high-performance concretes and to develop a material model.

The focus of the subproject “Load-induced increase of temperature in UHPC” is to investigate the increase in temperature of concrete specimens due to cyclic loading, which has been observed in some previous fatigue investigations. The thesis is that the induced temperature fields have a non-negligible influence on the damage process and the fatigue strength of UHPC. The significantly denser material composition, which causes greater internal friction, is assumed to be the reason for the phenomenon. The size and the speed of the temperature increase depending on the load frequency and regime as well as the largest grain.

Systematic experimental studies on the effect of the different parameters on the load-induced temperature fields and the degradation of the concrete material by fatigue loading are still pending, and will be completed within this project. The basis for the systematic investigations is the current state of knowledge. The strength of the concrete, the grain size, the specimen’s geometry, the loading parameters (e.g., upper stresses and load frequency) as well as the concrete age will be varied. The goal of the investigation is to quantify the temperature development as a function of the different parameters. Furthermore, we want to describe the influence of the temperature fields on the strains, the cracking and the concrete microstructure during the fatigue process. The project partner at TU Darmstadt will develop a material model that describes the fatigue behaviour of UHPC at high-frequency compressive stresses.