20 MN load frame

20 MN load frame

Since 2009, a load-bearing frame with a capacity of 20 MN has been part of the equipment of the Otto Mohr Laboratory. The current configuration allows pressure and tensile tests in a load range of up to 10 MN. An upgrade to 20 MN is possible. The horizontally mounted test frame is 2 m wide and 6.50 m long plus hydraulic cylinder and clamping device. It weighs 73 t and is suitable for ambitious material and component testing in quality control as well as in the context of research projects. In the 20 MN loading frame, for example, the load-bearing capacity, fatigue strength and characteristics of usability can be determined on large, very slim or even bulky samples.

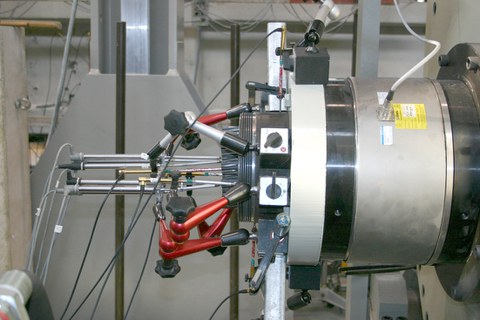

Measurement equipment at a tendon testedtest

Depending on customer’s specifications, tests can be carried out statically or cyclically according to different standards and guidelines (e.g. EAD16), for example on wires, strands, rods and couplings, or on cable systems. Measuring variables such as cable strain, anchor head deformation and wedge or strand movements can be recorded continuously.

The machine control allows a force, displacement or expansion controlled test procedure within the maximum available stroke of the hydraulic cylinder. The test load is transmitted from the hydraulic cylinder, which is anchored behind a solid steel plate, directly to the test specimen via a threaded rod with a diameter of up to 63.5 mm or an adapter construction for the load introduction. In addition, the test of tendons is possible with a sample diameter of up to 22 cm. The testing of smaller samples is also possible using adapter parts. Four protective tubes with a diameter of 400 mm each ensure the safety of personnel and equipment during the test execution. Long-time swing tests can be carried out with a maximum load of 8 MN and a frequency of up to 5 Hz, depending on the required expansion. During cyclic tests, the usual parameters can be measured, such as the change of the load, elongation or deformation, for example in the anchoring area. A combination with different measuring devices and methods, for example photogrammetry, is possible without any problems.

| Technische Informationen | Technical information | ||

| Maximale statische Prüfkraft | Maximum static test load | 250 kN | |

| Maximale zyklische Prüfkraft | Maximum cyclic test load | 200 kN | |

| Maximaler Kolbenweg | Maximum piston movement |

160 mm |

|

| Maximale Prüffrequenz und zugehörige Amplituden und Maximalkräfte (Auswahl) | Possible test frequencies and corresponding amplitudes and max. forces (selection) |

|

|

| Prüfraumbreite | Work space width | 500 mm | |

| Prüfraumhöhe | Work space clearance | 0–1000 mm | |

| Einspannlänge | Clamping length |

80 mm (unten und oben | below and above) |

|