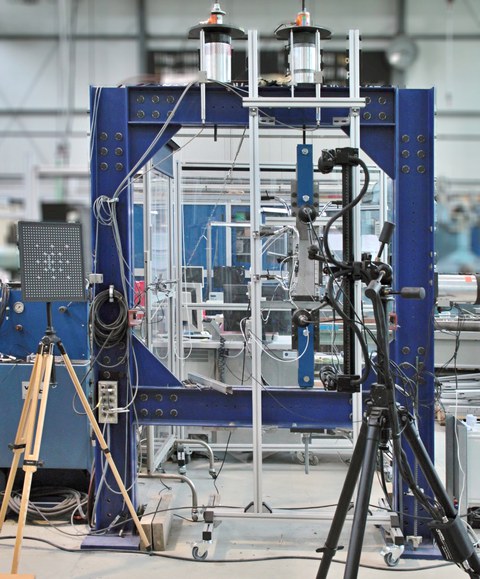

2020 Biaxial loading frame

The biaxial testing machine (in short: Biax) is used to perform uniaxial and biaxial static tensile tests on flat specimens, such as carbon concrete tensile specimens or crossed specimens. It is possible to simulate biaxial deformation states.

Tensile test in biax frame with heating stand

The Biax consists of a load frame with four hydraulic cylinders, which can be placed freely in the respective axis. This enables independent loading in two orthogonal axes. The size of the single-acting cylinders can be adapted to the required test load of up to 100 kN, depending on requirements. Different sizes of cylinders are available which are controlled by a load and stroke monitoring. A hydraulic unit supplies the cylinders with oil via servo valves. The specimens can be fixed in a hydraulic (1-axis testing) as well as in a mechanical clamping device (1- and 2-axis testing) with freely adjustable clamping pressure. Due to the open test frame the specimen can be inspected from all sides during the test. Additional measuring equipment can also be added without space problems. The Otto Mohr Laboratory also offers the possibility of measuring with 3D cameras and evaluation with the image correlation software ARAMIS. The sensors record coordinates, displacements and replacements of the surface without contact and independent of material. Thus, for example, the formation and development of cracks can be documented in detail.

Flat sample in open heating stand (tensile test)

In addition to various possibilities for the use of measuring technology, two heating stations including an exhaust air system are also available at the Biax. These can be integrated into the test stand either open or closed, depending on the test requirements. In case of a closed application, however, the choice of measurement technology is limited due to the heat load. The test specimen can be heated up to temperatures of up to 400 °C. These tests are mainly carried out if the material behaviour under fire load is to be investigated. For example, tensile tests were carried out on carbon concrete specimens under high temperature stress.

Due to the universal test frame of the Biax testing machine, tests can be carried out on other materials with versatile measuring possibilities.

| Technische Informationen | Technical information | ||

| Maximale statische Prüfkraft | Maximum static test load | 100 kN | |

| Maximale zyklische Prüfkraft | Maximum cyclic test load | 100 kN | |

| Maximaler Kolbenweg | Maximum piston movement |

160 mm |

|

| Maximale Prüffrequenz und zugehörige Amplituden und Maximalkräfte (Auswahl) | Possible test frequencies and corresponding amplitudes and max. forces (selection) |

|

|

| Prüfraumbreite | Work space width | 500 mm | |

| Prüfraumhöhe | Work space clearance | 0–1000 mm | |

| Einspannlänge | Clamping length |

80 mm (unten und oben | below and above) |

|