Multi-scale failure analysis with polymorphic uncertainties for optimal design of rotor blades

Abstract of the planned project content, taking into account the results from the first project phase

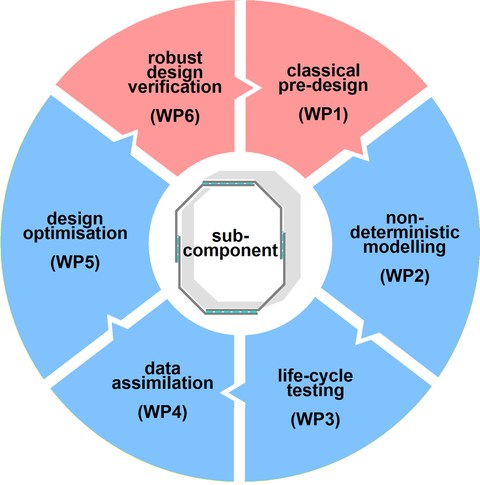

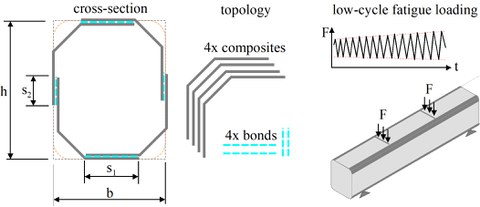

The goal of the project is to identify polymorphic uncertainties in structural design of rotor blades and to develop multi-scale (in space and time) non-deterministic models and numerical approaches, which are able to integrate these uncertainties into a typical chain of design, optimization, manufacturing, testing and lifetime maintenance. In order to reflect bending and shear deformations in the core beam of a rotor blade under wind loading, a new representative sub-component with a box cross-section is selected.

Objectives and working program for the second funding period

Whereas the main focus of the first period was dedicated to adhesive bonds in rotor blades, the emphasis of the second period is directed to the multiple failure mechanisms of critical components including cracking, debonding, buckling and low-cycle fatigue.

The first goal is to study the corresponding uncertainties on a representative sub-component comprehensively, in order to be able to validate predictions. This sub-component itself will be classically pre-designed and manufactured. The corresponding uncertainties will be identified and measured by use of non-destructive testing techniques at disposal.

The second goal is to develop non-deterministic models with polymorphic uncertainties for cracking, debonding, buckling and low-cycle fatigue damage, also including their interactions. These models will be implemented in a macro-scale parametric structural model able to simulate response under low-cycle fatigue loading. Such a cyclic quasi-static time function will be derived from the known representative load collectives for rotor blades, which simulate operation loads during service life.

The same quasi-static loading will be applied to the sub-component experimentally until failure, including comprehensive response measurements by optical, fiber-optical and traditional techniques. The third goal is to develop data assimilation approaches with polymorphic uncertainties and to justify them on the developed models and obtained measurements. Evidently, the main uncertainties can be then properly quantified and minimized.

The fourth goal is to optimize the topology, shape and size of the given sub-component by use of this validated parametric model with polymorphic uncertainties. The development of suitable methods for structural optimization under polymorphic uncertainties is an additional challenge.

Representative sub-component to be designed and tested

The robust optimal design of the sub-component will be finally compared to the original, classical pre-design. On this basis, the role of the polymorphic uncertainties in the entire chain "design, modelling, testing and optimization" can become directly visible and measurable. This unique possibility is the main highlight of the project.

Essential project goals and objectives

-

Development of a traditional pre-design for a representative sub-component

-

Non-destructive testing in order to measure structural and geometrical imperfections

-

Development of a parametric 3D multi-scale model

-

Investigations of multiple failure mechanisms (cracking, debonding, buckling, low-cycle fatigue)

-

Life-cycle testing under low-cycle fatigue loading in the framework of a four-point bending test

-

Data assimilation under polymorphic uncertainties

-

Design optimization under polymorphic uncertainties

-

Robust design verification

Robert Gruhlke

Dr. rer. nat. Robert Gruhlke

Weierstraß-Institut

M. Sc. Martin Drieschner

M.Sc. Martin Drieschner

Technische Universität Berlin

Fachgebiet Statik und Dynamik