Bionanotechnology

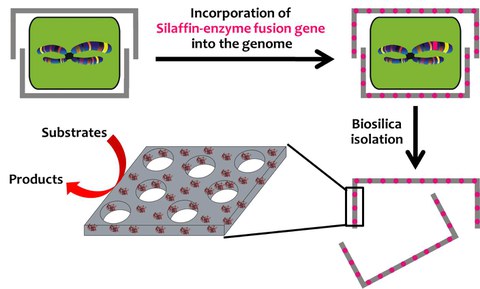

The silica structures produced by diatoms are low-cost materials that exhibit many features interesting for a broad range of nanotechnological applications including membranes for biomolecule separations, size-selective sensors, microelectro-mechanical systems (MEMS), and masks for microfabrication. To fully exploit the nanotechnological potential of diatom silica, the Kröger group has recently developed a novel method to introduce additional functionalities into the diatom silica. This functionalization method is based on molecular genetic engineering of the silica biomineralization process in the diatom T. pseudonana. Recombinant genes that encode silaffin Sil3 fused to a functional protein of choice, have been incorporated into the T. pseudonana genome through techniques established by the Kröger group. The silaffin-domain is responsible for targeting the fusion protein for incorporation into the forming silica, thus stably immobilizing the functional domain in the frustule after completion of silica biogenesis. The method has been coined Live Diatom Silica Immobilization (LiDSI) , and has been successfully used to immobilize in the diatom silica various enzymes including cofactor-dependent and multimeric enzymes. Attachment to the biosilica had a stabilizing effect on the enzymes.

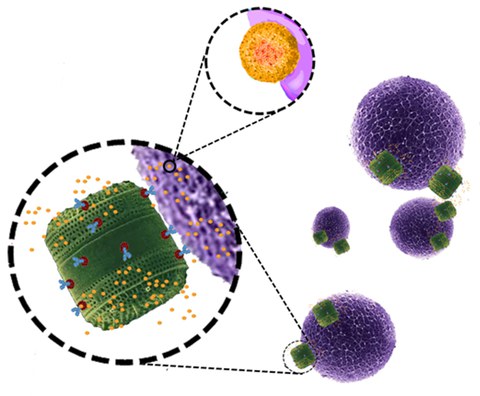

Genetically engineered diatom biosilica (green) containing liposome-encapsulated drug molecules (yellow) can be targeted to lymphocyte cells in suspension (purple) by functionalizing the biosilica surface with antibodies

The method represents a new paradigm for the sustainable bio-enabled production of complex nanostructured materials with tailored functionalities. A compelling advantage of LiDSI is that the enzyme does not need to be isolated prior to immobilization. This should be particularly advantageous for enzymes that are expensive to isolate and prone to rapid denaturation in vitro. Because of the excellent mechanical and mass transport properties of diatom silica enzyme-functionalized diatom cell walls may be attractive materials for flow-through devices from very small (microfluidics) to large scale (flow-through reactors).