Artifical Intelligence

Already in the early 1990s, a number of AI methods were available and used for data analysis, decision support, and process optimization. Today, due to increasing computational power, higher data availability, and newly developed modeling approaches, which can describe even complex processes in a more efficient way, AI-based methods find more applications in the process industry.

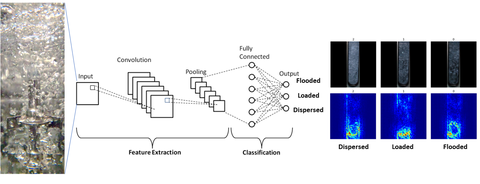

Machine learning is one of the central fields of the AI technology landscape. It implies a wide variety of approaches such as neural networks, random forests, K-Means for solving regression, classification and clustering tasks, and reinforcement learning. The main feature of these methods is the use of data for modeling. The flexible model structure allows the representation of very complex interrelationships.

Process data can be used to determine such relationships, which can help to better understand process and plant behavior. These correlations can be found by AI-supported information extraction about process states and product properties from measurement data, including time series and image data in laboratory and production. This should address various problems in the area of monitoring and optimization, e.g., uncertainties about the current operating regime should be reduced, possible failures or undesirable states should be detected earlier, and systematic deviations should be automatically diagnosed and taken into account during the process control. This increases the economic efficiency of chemical and biotechnical production processes through optimal use of the operating window, higher plant availability, and process and plant safety.