Fields of work

Simulation

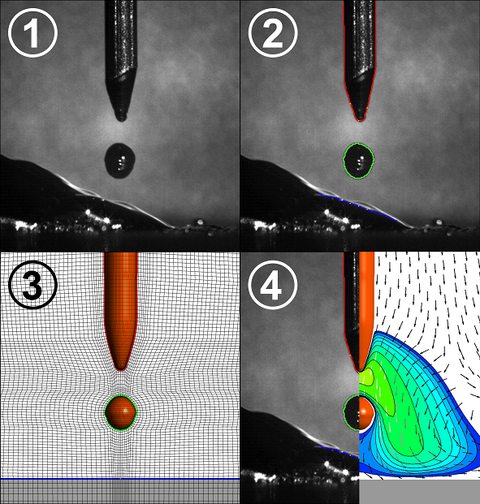

- Modeling of the arc column and the drop zone, taking metal vapor influence, radiation transport and external magnetic fields into account

- Modeling of the material transition and weld pool dynamics

- Torch optimization with regard to shielding gas coverage and thermal load

- Simulation of fumes emitted during welding and their extraction

- Calculation of joint geometry and penetration profile

Diagnostics

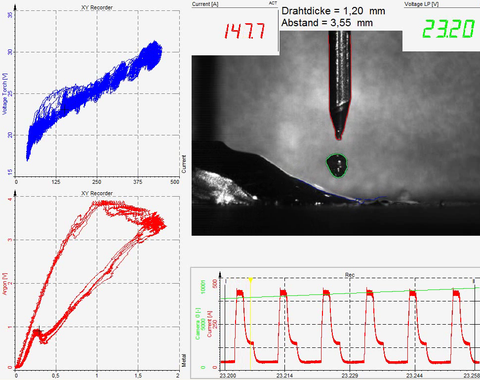

- High-resolution process variable analysis in the MHz range

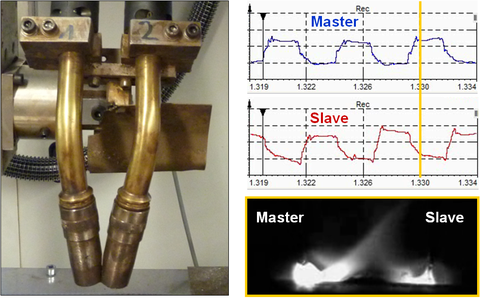

- Time-synchronized high-speed cinematography of up to 500,000 FPS

- Flow visualization (PIV, Schlieren technique)

- Determination of energy density and arc pressure

- Spatially resolved measurements of the oxygen concentration in the area immediately surrounding the workpiece

- Measurement of welding fume emissions

Application

- Torch development (incl. cathode-focused TIG torch and plasma-laser hybrid welding head with coaxial beam guidance)

- Development of high-performance processes (including tandem GMAW, plasma and TIG keyhole welding, high-speed arc brazing)

- Analyses for magnetic arc deflection

- Welding tests in all positions and material analysis

Technical equipment

- Computer cluster (40 computing nodes, 172 GB RAM, 10 TB RAID 5)

- Photron SA4 high-speed camera

- Cavilux 500HF pulsed diode laser light source

- DEWETRON measuring system (1 MHz sampling rate)

- TIG, plasma, gas metal arc welding (GMAW) and tandem GMAW power sources

- Cold and hot wire feed

- 6-axis industrial welding robots, rotating mechanisms, linear axes

- Scanning election microscope (SEM), energy-dispersive X-ray (EDX), reflected and transmitted light microscopy, hardness testing, static and dynamic test methods