Simulation-aided design of solid lubricant coatings (LUBRICOAT)

Promoter: Sächsische AufbauBank (SAB)

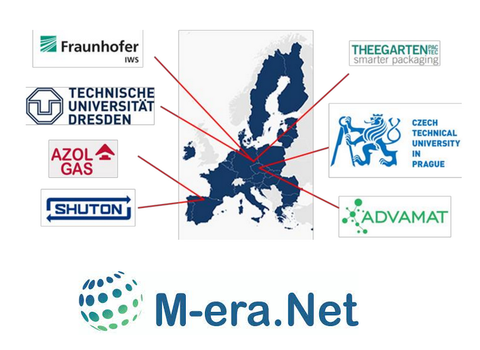

Cooperation partners: Czech Technical University of Prague, AdvaMat s.r.o.,

Fraunhofer IWS, Technische Universität Dresden, Theegarten-Pactec, SHUTON, S.A., AZOLGAS, S.L.

Current time: 01.06.2021 - 31.05.2024

Project ambition

The implementation of a green revolution and sustainable engineering is closely related to tribology, which is related to energy consumption, wear and component failures across all industries. 25 % of all energy losses worldwide are due to friction, and about 1-3 % of GDP could be saved every year by reducing wear and maintenance. Wasted material resources, which amount to hundreds of billions of € per year worldwide, give an idea of the vast environmental impact due to wear. Tribology plays an equally crucial role in reducing pollution, NOx emissions and the carbon footprint, which are closely related to the effectiveness of contacting surfaces and interfaces. The core aim of the proposed project is the simulation-based design on ultra-hard solid lubricant coatings providing low friction in a range of sliding conditions. Members of our consortium are pioneering solid lubricant coatings based on TMD, such as MoS2 combined with carbon. We were among the first to describe the formation of ultra-low friction tribolayer and to show that such coatings can reach superlubricity. We are pioneering atomistic simulations to understand their intrinsic friction behavior and sliding induced structural information. We have developed super-hard diamond-like coatings (ta-C), and we are the first to deposited MoS2 by laser arc technology. Thanks to recent investments and interaction with the private sector, our research is moving from laboratory to an industrial scale.

Partners

Czech Technical University of Prague

The project is coordinated by Prof. Tomas Polcar, head of the Advanced Materials Group based at the Department of Control Engineering, Faculty of Electrical Engineering. The group was launched in 2009 and soon became one of the most dynamic groups at the university. It consists of 1 Full Professor, 3 Assistant Professors (research tenure track), 13 postdoctoral researchers, and 5 PhD students. The group is multidisciplinary, with the main emphasis on nanoscale material science. Tribology represents the most significant activity, and the group is well known in the area of solid lubrication and the development of low-friction wear resistant coatings.

AdvaMat s.r.o.

AdvaMat is a university start-up, which was set up to transform laboratory results into engineering practice. It uses an industrial size deposition chamber (CemeCon 800 MLR, upgraded) to design and sell coatings for high-added-value applications. The company developed new multilayered TiAlCrN coatings for molds, stress-free wear-resistant DLC coatings for optical applications, and MoSe2/DLC solid lubricant coating for an aerospace actuator.

Fraunhofer IWS

The Fraunhofer society is a non-profit research organisation with a special focus on applied research. The Fraunhofer Institute for Material and Beam Technology (Fraunhofer IWS) is specialized in laser and surface technologies. The core business of the department "Carbon Coatings" is the development of coating technology, coating systems and necessary deposition parameters as well as coating characterization, using self-developed and standard methods with extended evaluation models. Within the last years, a new laser-assisted vacuum-arc carbon evaporation source (Laser-Arc) was developed and transferred to industry, which successfully enabled mass production of superhard carbon coatings (ta-C) for automotive engine components. Resources of the 15 member team consist of several customized PVD coating systems and highly-sophisticated nano- and micro-mechanical testing equipment, including two tribometers.

Technische Universität Dresden

At the Institute of Manufacturing Technology (TUD-IF) the basics of the main fields of manufacturing technology are investigated and the corresponding production processes are further developed. In particular, the chair for Large Area Based Surface Structuring (LMO) is focused on the development of new laser-based methods and technologies for high-speed surface patterning of materials, as well as their impact on friction and wear properties. In the last years, LMO has developed and installed a highly specialized and unique tribometer to investigate fundamental tribological processes of contacting surfaces in vacuum and various atmospheres. In cooperation with the Ion Beam Center (IBC) at Helmholtz-Zentrum Dresden-Rossendorf (HZDR), in-line tools for fundamental structural and chemical analysis can be used.

Theegarten-Pactec

As one of the world's leading manufacturers in the packaging technology sector, Theegarten-Pactec develops high quality and intelligent packaging machines for small-sized confectionery products and other foodstuffs, such as stock cubes, as well as for non-food items, e.g., detergent tablets. Theegarten-Pactec has experience for many years in the design and manufacturing of machines with the highest mechanical complexity under various demanding tribological conditions.

SHUTON, S.A.

SHUTON is a leading company in the manufacturing of high precision ball screws located in the Basque Country, central and leading area in the machine-tool industry in the North of Spain and throughout Europe. SHUTON is a part of the Nadella Group since 2020, and with more than 45 years of experience in the development and manufacture of high precision ball screws, Shuton’s R&D resources include its own R&D department in which 4 engineers work and which is joined by resources from other departments for the different projects, making a total of 17 engineers from different specialties.

AZOLGAS, S.L.

AZOLGAS is a SME belonging to an international industrial group dedicated to the design, development, manufacture and marketing nitrogen gas springs for metal stamping components. AZOLGAS continues its commitment to research and innovation: developping innovative and safe technical solutions for the new challenges of metal stamping, carrying out exhausting tests in testing laboratories, cooperating with specialized Technology Centers, registering patents, offering the widest range of gas springs in the market and designing and implementing customized applications.