AdHyBau

Novel designs for structures in electric drives with cryogenic cooling

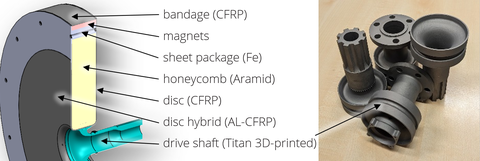

Generative manufacturing technologies enable optimised cooling systems and a specific coil design to increase the power density of next-generation electric motors. As part of the AdHyBau research project, SIEMENS AG, MT Aerospace AG, the Fraunhofer Institute for Mechanics of Materials IWM, the Institute of Technical Physics (ITEP) at the Karlsruhe Institute of Technology (KIT) and the ILK are developing new additive processes and fibre composite-metal hybrid designs for use in cryogenic environments. End-to-end design, simulation and material qualification processes are being developed in order to put a new type of electric drive into operation as a virtual prototype. The main objective of the work to be carried out at the ILK is to research new fibre composite-metal hybrid designs. The combination of high-performance fibre composite materials with additively manufactured metallic elements enables structures that are significantly enhanced in terms of their functionality and performance. This key technology contributes to power-dense, efficient and low-noise drives and is therefore a central component of the mobility of the future.

left: new rotor concept for an electric aircraft motor; right: 3D-printed driveshafts.

01.05.2020–31.12.2023

© TUD/ILK

© TUD/ILK

Chair of Lightweight Systems Engineering and MultiMaterial Design

NameProf. Dr.-Ing. habil. Maik Gude

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Lightweight Engineering and Polymer Technology

Visitors Address:

DÜR, Floor 0, Room 71 Holbeinstr. 3

01307 Dresden

Deutschland

- Martin Pohl (Joining Technologies)

Publications Martin Pohl | TU Dresden