PRILLIAND

Development of an additive production technology for manufacturing plastic-based components for maritime applications

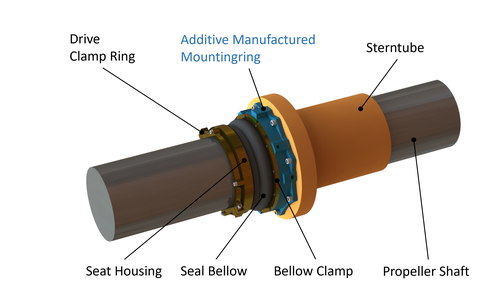

Maritime sealing systems are subject to high mechanical and media stresses and are essential for the safe and economical operation of ships. In this context, the stern tube system, as a component of the ship's propulsion system, describes a bearing for supporting the ship's shaft in the hull and prevents seawater from penetrating through the drive shaft channel. Due to the individual sizes and the small quantities per ship, the individual components used in this process have so far been manufactured as very time-consuming and cost-intensive large-scale constructions in metallic casting alloys with extensive reworking.

The aim of the joint project is therefore to make the conventional production of product solutions for sterntube system components available on the market more sustainable. By using LSAM (Large Scale Additive Manufacturing) production technology in combination with modern material systems, a two-part housing for a sterntube seal was designed and realised in a material and production-compatible manner, significantly increasing its ecological and economic efficiency compared to conventional metallic components. To investigate the sustainability of additive manufactured maritime components, an end-to-end recycling strategy was developed to return the base materials of the sterntube seal housing to the manufacturing process. The high level of customisability that can be achieved at the same time also enables quick and cost-effective adaptation to customer requirements. PRILLIAND thus forms the basis for customised and efficient small series production of large structures for maritime applications.

Illustration of the installation situation of the additive manufactured mounting ring in the stern tube system.

01.04.2021–30.09.2024

Consortium Leadership

© TUD/ILK

© TUD/ILK

Chair of Lightweight Systems Engineering and MultiMaterial Design

NameProf. Dr.-Ing. habil. Maik Gude

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Lightweight Engineering and Polymer Technology

Visitors Address:

DÜR, Floor 0, Room 71 Holbeinstr. 3

01307 Dresden

Deutschland

- Johanna Maier (Novel Materials and Special Processes)

Publications Johanna Maier | TU Dresden - Tobias Kastner (Novel Materials and Special Processes)

Publications Tobias Kastner | TU Dresden