DataPro-3DCP

Data-Process for 3D Concrete Printing

| Funding: | Federal Ministry for Economic Affairs and Energy, Industrial Collective Research |

| Funding reference number: | IGF_2024-01150 |

| Partner: |

Institut für Baubetriebswesen |

| Project support committee: |

AEC3 Deutschland GmbH |

| Duration: | 07/2025 - 06/2027 |

| Contact: | Paul Plaschnick |

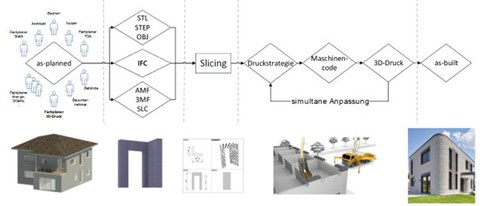

The automation of components using concrete 3D printing is crucial for increasing productivity despite a shortage of skilled workers, rising costs and high quality requirements. However, there is currently a lack of standardized digital processes and interfaces, as many developments are proprietary. This hinders widespread introduction and leads to additional work in planning, approval and production. In order to use the technology economically and reliably, an end-to-end digital chain from BIM planning to machine control (e.g. G-code) and digital documentation "as built" is required.

The DataPro-3DCP research project aims to create a pre-normative basis for standardized data flows and, in particular, for extrusion-based printing processes. Structural, concrete technology and machine-specific requirements, material behavior, weather influences and "on-the-fly" regulations are taken into account. The aim is the automated conversion of BIM models into ready-to-use control data.

Digitale Prozessabläufe und Standardisierung beim Beton-3D-Druck

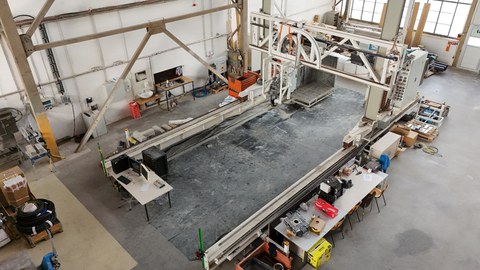

The validation is carried out at the TUD test stand with a printer for components up to 6 m × 3 m × 3 m. The creation of a generally applicable industry standard, comparable to established standards in the construction sector, is intended to lower market entry barriers, promote innovation and advance the digitalization of construction processes.

TUD-Versuchsstand