Fiber spinning technologies

Dipl.-Ing. Martin Hengstermann, research fellow and doctoral candidate at the ITM, at the special carding plant of the ITM for the use of recycled carbon fibers (rcf) for continued use in load-bearing composite components - awarded the German Resource Efficiency Award 2016

Research activities for fiber spinning technology at the ITM include a multitude of projects. The focus is on the use of high-performance fiber materials for technical applications. These efforts are supported by the DFG (basic research), the AiF (application-oriented basic research), and by the IGF, ZIM and BMBF for the company-specific realization of new methods and products. The ITM also works with industrial and service partners. All current machine technologies from spinning preparation to spinning and winding of various yarn structures, and required testing equipment for the characterization of yarn structures are available at the ITM.

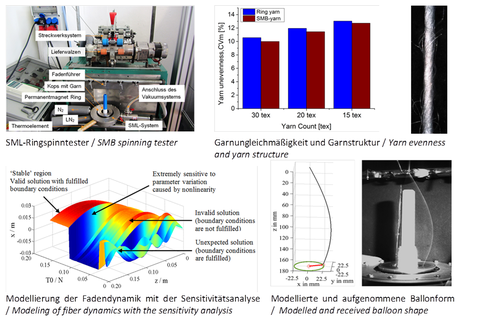

The simulation-based development of a frictionless high-performance twist insertion based on superconductor technology as a replacement for conventional ring/traveler systems is a current focus of ITM research activities. The developed prototype of this newly patented spinning process was successfully presented to an enthusiastic expert audience at the ITMA convention in Milan in 2015. By realizing a superconductive magnet bearing, productivity was increased by up to 200 % in comparison to conventional ring spinning processes, which constitutes an industrial breakthrough.

Depiction of the SML principle on a ring spinning machine

German Resource Efficiency Award 2016 for the ITM at TU Dresden and the Oskar Dilo Maschinenfabrik KG for the realization of a unique method for the production of rCF high-performance hybrid yarns for fiber-reinforced composite materials © BGR/Fotothek

One particular focus of research activity comprises the use of recycled carbon fibers (rCF) for renewed use in load-carrying composite components. Using optimized spinning processes, these rCF are spun either into pure rCF staple fiber yarns or into hybrid yarns with additional matrix fibers for the thermoplastic processing. For this, the machine technologies of conventional yarn production methods are significantly modified and partially re-developed with industry partners to ensure a gentle processing of the recycled carbon staple fibers. On February 16th, 2017, the expert conference “Rohstoffe effizient nutzen – Erfolgreich am Markt” (“Efficient resource use – Sucessful Business”) at the Federal Ministry for Economy in Berlin awarded the German Resource Efficiency Award 2016 in the Research category to the ITM-developed research project “Resource-efficient use of recycled carbon fibers based on a development of a technology for the industrial production of hybrid yarns to be used in heavy-duty CFR components”.

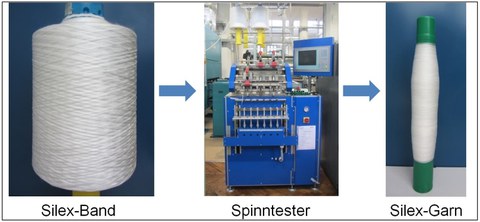

Other research activities include the development, modification and adaption of available thread production technologies to achieve an industrially applicable method for the spinning of fine staple fiber yarns from sensitive high-performance fiber materials (e.g. basalt and special glass fibers), the processing of metal fibers, and the production of sensor and functional yarns.

Production of high-temperature-resistant Silex yarn

To analyze processes and machine components, modern measuring technology (high-speed video, acceleration sensors, etc.) and ITM-developed in-situ methods for thread dynamic recording are used.

Contact person:

© Mirko Krziwon

© Mirko Krziwon

Mr Dr.-Ing. Anwar Abdkader

Head of multi-material yarn structures for high-tech applications

Send encrypted email via the SecureMail portal (for TUD external users only).

Visitor Address:

Breitscheidstraße 78, House D, Roum 1.1.11

01237 Dresden

Deutschland