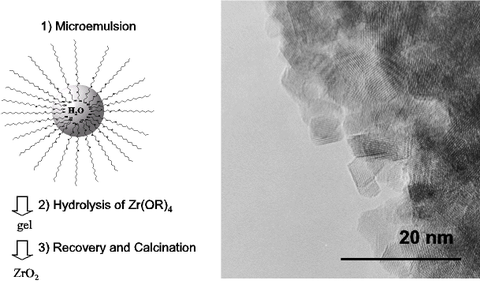

Space Confined Sol-Gel Processes

Reverse microemulsions consist of water droplets 1-100 nm in size which are dispersed in a non-polar solvent with the aid of a surfactant. The hydrolysis of metal alkoxide precursors converts the water droplet into a hydroxide particle the size of which is controlled by the initial size of the water droplet. The radius of the droplet criticallly depends on the water/surfactant ratio in the microemulsion. Thus the final particle size and morphology is controlled with the microemulsion composition. Such space confined sol-gel processes can be used to make ultrafine powders with very high accessible surface area. We have used the microemulsion synthesis for the design of new sulfated zirconia catalysts which are used for skeletal isomerization reactions. In this process the promotor (sulfuric acid) is dissolved in the micelles and incorporated into the solid during the condensation of Zr(OR)4. Combined synthesis and evaluation of the catalytic properties is the key for the design of new high-performance catalysts.

- H. Althues, S. Kaskel, “Sulfated Zirconia Nanoparticles synthesized in Reverse Microemulsions – Preparation and Catalytic Properties”, Langmuir 2002, 18, 7428-7435.

- J. Sauer, S. Kaskel, M. Janicke, F. Schüth, Zirconia nanoparticles in ordered mesoporous material SBA-15 Stud.Surf.Sci.Catal. 2001, 135, 315.