Equipment

Our laboratory has extensive equipment for the production of normal strength concrete and various special concrete types with and without reinforcement. Also, a wood workshop and a metal workshop allow us to work with other materials. Some testing machines are also presented in more detail:

- Universal testing machine ZD 2500

- Hydropulse testing machine 1000 kN

- Hydro pulse testing machine Sinus 250 kN

-

4-column universal testing machine Z 250

- Biaxial loading frame

- Triaxial testing machine

- 20 MN load frame

- Hydraulic test cylinder system

- Drop tower

Molds

Manufacturing of special elements

- Standard steel molds for 10 cm and 15 cm cubes, cylinders (Ø = 150 mm, h = 300 mm) and prisms (10 × 10 × 40/50 cm, 15 × 15 × 60 cm and 16 × 4 × 4 cm)

- Formwork for standard tests on textile- and carbon-reinforced concrete

- Various specially shaped (e.g. for tensile strength tests on concrete) and custom-made molds and products

Mixers

Mixing of fine grained concrete

- Zyklos ZK 50 HE (12–30 liters)

- Pemat/Zyklos ZK 150 HE (30–100 liters)

- Pemat PMPR 500 (100–350 liters)

- Cement mortar mixer, Otto Mondschein Maschinenbau type ZMM5

Concrete consolidation

Pouring of carbon-reinforced concrete

- Bottle vibrator

- Vibrating table

- Shock table

- Needle testing device

- Pore volume measuring device

Other equipment

- Vacuum chambers for concreting under negative air pressure

- Various scales, laboratory hotplates, vibrators

- Mortar spreading table and concrete spreading table, each with metal mold

- Slump testing device

- Two climate chambers in the standard climate area and drying cabinets

- Climate cabinets for a temperature range from –40 to 80 ° C

- Temperature and humidity recorders

- Concrete saws, core drilling machines, rotary hammers

- Double-surface grinding machine

- Cabinet for heat treatment of concrete components

Deburring a wire strand

Selection of equipment

- Extensive, well-assorted selection of standard tools

- Router, saw, pillar drills, steel planer

- Torque wrench

- Levelers

Selection of equipment

- Extensive, well-stocked selection of standard tools

- Router, jointer

- Workbenches

- Drill press

- Band saw, circular saw

- Planer

We can use strong floors with a total area of 126 m². We have a large number of test frames and test cylinders of various geometries and capacities between 10 kN and 10 MN at our disposal.

Strong floor in the Mohr hall

Strong floor in the Mohr hall

- Area: 21.0 × 6.0 m

- Grid: 1.50 m

- Capacity per test portal: up to 1 MN, can be combined

- Testing of individual elements up to 10 t weight and 5 m height possible

Strong floor in the technical center

- Area: approx. 15.0 × 10.5 m

- Grid: 1.50 m

- Load capacity up to 1 MN

Variable portal frames and equipment

- Hmax = 4.00 and 5.25 m and 2 × Hmax = 6.00 m

- Various load cells between 1 kN and 10 MN

We also have various standard and special testing machines, e.g. for determining multi-axial material strengths or strengths at high strain rates (impact tests) and for carrying out tests under the influence of temperature.

- DB 6000-4,0:

Maximum load: 6 MN pressure, variable clearance heights: up to 4.0 m - DB 6000-1,5:

Maximum load: 6 MN pressure, variable clearance heights: up to 1.5 m - DB 3000-0,6:

Maximum load: 3 MN pressure, variable clearance heights: up to 0.6 m - DB 600:

Maximum load: 600 kN pressure - ZD 1000:

Maximum load: 1 MN pressure resp. tension - ZD 100:

Maximum load:100 kN pressure resp. tension - Tension-compression test machine (type Zwick) with three load axes:

Maximum loads: 10, 50 and 250 kN pressure resp. tension

- Test cylinder system with at least two test cylinders each with maximum load heights between 10 kN and 1 MN

- Pulsator unit for cyclic loading with up to 5 Hz load frequency (depending on sample deformation)

- Hydropuls testing machine with two load frames:

- frame 1: maximum static load: 1 MN compression or tension

- frame 2: maximum static load: 250 kN compression or tension

- maximum cyclic load: 80 % of the static value - Z 100: maximum static load: 100 kN compression or tension, maximum cyclic load: 80 kN compression or tension

- Universal testing machine ZD 2500:

- maximum static load: 2.5 MN compression or tension

- maximum cyclic load: 500 kN compression or tension

- maximum test frequencies and amplitudes (selection): 25 Hz – amplitude 3.0 mm | 10 Hz – amplitude 7.5 mm | 3 Hz – amplitude 25 mm

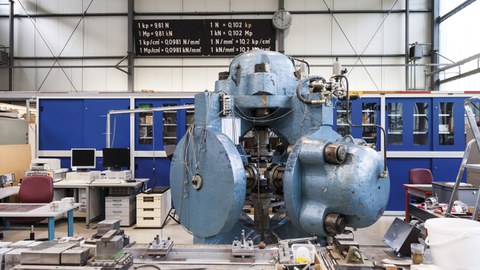

Triaxial testing machine (more details here)

The "Blue wonder" - the triaxial testing machine in the OML

- loads up to 200 kN in tension or 5 MN in compression per axle

- loads can be introduced using rigid plates or load-bearing brushes of different geometries

- test specimen: cubes with 10 cm edge length (standard), max. 30 cm cubes

Biaxial testing machine (more details here)

- max. 100 kN tension per axle

Triaxial cell

- 125 kN maximum vertical compression

- up to 5 MPa radial pressure

- specimen: cylindrical samples with a diameter of 2.54 cm and a height of 5.08 cm

- heating up to 150 °C possible

Horizontal 20 MN load frame (more details here)

- 10 MN current maximum load (can be upgraded to 20 MN)

- maximum (free) test length: 5 m for compression tests

- maximum (free) test length: 7.50 m for tensile tests

Horizontale Kettenzugmaschine

- Maximallast: 400 kN

- maximale Einspannlänge: 6 m

Bending test on an timber truss beam

10 MN testing machine

- specimen sizes up to 2.5 m (width) × 15 m (length) × 3.7 m (height)

- currently maximum weight of specimens: 60 t (can be upgraded to 120 t)

Split Hopkinson bar for high-dynamic load tests

- maximum load rate of 35 m/s

- for testing cylindrical test specimens with Ø = 50 mm and ≤ 150 mm length for compression tests resp. ≥ 200 mm length for spallation tests

- kinetic energy of the impactor can reach up to 1.8 kJ

Biaxial split Hopkinson bar for high-dynamic load tests

Biaxialer SHB im Mohr-Technikum

- maximum load rate: 35 m/s

- test specimen: 60 × 60 × 60 mm

- kinetic energy of the impactor: up to 1.8 kJ per axle

Small drop weight test stand

- maximum fall height: 5.0 m

- maximum drop weight: 49.1 kg

Large drop test rig (drop tower) (more details here)

- free falling impactors and acceleration system

- maximum drop height: 11.0 m

- free falling configuration:

maximum drop weight: 2500 kg, maximum impact speed: 15 m/s - accelerated configuration:

maximum drop weight: 160 kg, maximum impact speed: 160 m/s

Fall sled

- Devices for 3- and 4-point bending experiments for standard tests

- Model statics test rigs for the investigation of truss and shell models

- Creep stands with mechanical or pneumatic load generation

- Panel test stand

- Façade test stand for panels up to 2.4 × 2.4 m

- Test rig for shear tests

- Equipment for carrying out tests with variable temperature loading

- Test stand for testing panels under wind load

- Several control panels

A large number of load frames are available for in situ tests of structures.

- Various load frames for in situ tests on bridges, ceilings, columns, masts, railings, etc.

- Ultrasonic measuring device

- Profometer 3 (reinforcement location)

- Rebound hammer

- (Video) endoscopy device

- Equipment for taking drill cores

We are equipped with extensive measuring and storage technology for data acquisition, which includes a wide range of measuring devices and measuring equipment, including photogrammetry and high-speed cameras.

- Measuring amplifier

- MGC, MGCplus

- Quantum MX840

- Spider 8 - Multipoint measuring device UPM100

- Close-range photogrammetry

- AICON 3D system with four cameras and accessories

- GOM ARAMIS 3D with two cameras (5 MP) and accessories

- GOM ARAMIS 2D with four cameras (12 MP) and accessories

- Various SLR and compact camera systems - Transient recorder for measurements during high-speed tests

- AOS measuring device for fiber Bragg grating sensors

- Photron Fastcam SA5 high-speed cameras

- Devices for remote monitoring of measurements

- Data logger

- Strain gauges

- Inductive displacement transducers

- Fiber Bragg grating

- Strain and acceleration transducers

- Dynamic force sensors

- Laser vibrometer for non-contact displacement and velocity measurement over long distances

- Thermocouples and humidity sensors (air humidity)

- Extensometers

- Draw-wire sensor

- Anemometer

- Leveling instrument

- Theodolite

- Various distance measuring devices

- Inclinometer: Angle determination up to +/– 30°

- Inclinometer LSOC-0120: angle determination up to +/–3°

- Various mechanical length measuring devices, including dial gauges, setting strain gauges (Pfender/setting strain gauge type), micrometer or micrometer screw

- Hand-held shaker

- Magnetic measuring stand

- Spring tension meter

- Various force measuring clamps

In addition, here are some details about our other equipment.

Lift cranes

- Mohr hall: lifting capacity 5 t each

- Technical center, concreting hall area: lifting capacity 5 t

- Technical center, testing hall area: lifting capacity 10 t

Other

- Forklift truck (load capacity: 3.5 t)

- Welding equipment (electric and autogenous)

- Mobile oil pressure units

- Sandblasting unit

- Heavy-duty trucks, load capacity: 60 t

- Equipment for lifting and moving construction-related loads of up to 120 t using hydraulic lifting technology

- CNC milling machine with 3-axes-working area

- 3D printer for production of custom-made accessories

Heavy transport at the OML: the split Hopkinson bar gets a new home