Ausstattung

Unser Labor verfügt über eine umfangreiche Ausstattung für die Herstellung von Beton verschiedenster Zusammensetzung einschließlich Sonderbetone mit und ohne Bewehrung und ist im Folgenden aufgeführt. Eine Holzwerkstatt und eine Metallwerkstatt ergänzen die Ausstattung. Einige Prüfmaschinen werden zudem näher vorgestellt:

- Universalprüfmaschine ZD 2500

- Hydropulsprüfmaschine 1000 kN

-

Hydropulsprüfmaschine Sinus 250 kN

-

4-Säulen-Universalprüfmaschine Z 250

-

Biaxial-Prüfrahmen

-

Triaxialprüfmaschine

-

20-MN-Belastungsrahmen

-

Hydraulische Prüfzylinderanlage

Formen

Anfertigung von Sonderbauteilen

- Stahl-Standardformen für 10er und 15er Würfel, Zylinder (Ø = 150 mm, h = 300 mm) und Prismen (10 × 10 × 40/50 cm, 15 × 15 × 60 cm und 16 × 4 × 4 cm)

- Schalungen zur Herstellung der Standard-Textilbetonproben

- Verschiedene Sonderanfertigungen, wie z. B. Spezialformen für Zylinder mit Einschnürung (Betonzugfestigkeit)

Mischer

Herstellen von Feinbeton

- Zyklos ZK 50 HE (12–30 Liter)

- Pemat/Zyklos ZK 150 HE (30–100 Liter)

- Pemat PMPR 500 (100–350 Liter)

- Zementmörtelmischer, Otto Mondschein Maschinenbau Typ ZMM5

Verdichtung

Betonherstellung im Gießverfahren

- Flaschenrüttler

- Rütteltisch

- Schocktisch

- Nadelprüfgerät

- Porenvolumen-Messgerät

Sonstige Ausstattung

- Vakuumkammern für die Betonage unter Unterdruck

- Diverse Waagen, Laborheizplatten, Vibratoren

- Mörtelausbreittisch und Betonausbreittisch, jeweils mit Metallform

- Grundplatte und Metallform für Slump-Prüfung

- Zwei Klimakammern im Normklimabereich und Trockenschränke

- Klimaschränke für den Temperaturbereich von –40 bis 80 °C

- Temperatur- und Feuchtigkeitsschreiber

- Betonsägen, Kernbohrgeräte (verschiedene Durchmesser), Bohrhämmer

- Doppel-Planarschleifmaschine

- Schrank zur Wärme(nach)behandlung von Betonbauteilen

Entgraten einer Litze

Auswahl der Ausstattung

- Umfangreiche, gut sortierte Auswahl an Standardwerkzeugen

- Fräse, Säge, Ständerbohrmaschinen, Stahlhobelmaschine

- Drehmomentenschlüssel

- Nivelliergeräte

Auswahl der Ausstattung

- Umfangreiche, gut sortierte Auswahl an Standardwerkzeugen

- Fräse, Abrichte

- Werkbänke

- Ständerbohrmaschine

- Bandsäge, Kreissäge

- Hobelmaschine

Aktuell stehen uns Aufspannfelder mit einer Gesamtfläche von 126 m² und eine große Anzahl von Prüfportalen und Prüfzylindern unterschiedlichster Geometrie und Leistungsfähigkeit zwischen 10 kN und 10 MN zur Verfügung.

Spannfeld im Mohrbau

Aufspannfeld in der Mohr-Halle

- Fläche: 21,0 × 6,0 m

- Raster: 1,50 m

- Kapazität je Prüfportal: bis 1 MN, kombinierbar

- Prüfung von Einzelelementen bis zu 10 t Gewicht und 5 m Höhe möglich

Aufspannfeld im Technikum

- Fläche: ca. 15,0 × 10,5 m

- Raster: 1,50 m

- Lastkapazität bis 1 MN

Variable Portale und Ausrüstung

- Hmax = 4,00 und 5,25 m sowie 2 × Hmax = 6,00 m

- Verschiedene Kraftmessdosen zwischen 1 kN und 10 MN

Weiterhin besitzen wir verschiedene Standard- und Spezialprüfmaschinen, z. B. zur Bestimmung von mehraxialen Materialfestigkeiten oder von Festigkeiten bei hohen Dehnraten (Impaktversuche) sowie zur Durchführung von Versuchen unter Temperatureinfluss.

- DB 6000-4,0:

Maximallast: 6 MN Druck, lichte Einbauhöhe: bis 4,0 m - DB 6000-1,5:

Maximallast: 6 MN Druck, lichte Einbauhöhe: bis 1,5 m - DB 3000-0,6:

Maximallast: 3 MN Druck, lichte Einbauhöhe: bis 0,6 m - DB 600:

Maximallast: 600 kN Druck - ZD 1000:

Maximallast: 1 MN Druck bzw. Zug - ZD 100:

Maximallast: 100 kN Druck bzw. Zug - Zug-Druck-Prüfmaschine (Typ Zwick) mit drei Lastachsen:

Maximallasten: 10, 50 und 250 kN Druck bzw. Zug

- Prüfzylinderanlage mit mindestens je zwei Prüfzylindern mit maximalen Lasthöhen zwischen 10 kN und 1 MN

- Pulsatoranlage mit bis zu 5 Hz Lastwechselfrequenz (abhäng von der zugehörigen Prüfkörperverformung)

- Hydropulsprüfmaschine mit zwei Belastungsrahmen:

- Rahmen 1: statische Maximallast: 1 MN Druck bzw. Zug

- Rahmen 2: statische Maximallast: 250 kN Druck bzw. Zug

- zyklische Maximallast: jeweils 80 % vom statischen Wert - Z 100: statische Maximallast: 100 kN Druck bzw. Zug, zyklische Maximallast: 80 kN Druck bzw. Zug

- Universalprüfmaschine ZD 2500:

- max. Last statisch: 2,5 MN Druck bzw. Zug

- max. Last zyklisch: 500 kN Druck bzw. Zug

- Maximale Prüffrequenzen und Amplituden (Auswahl): 25 Hz – Amplitude 3,0 mm | 10 Hz – Amplitude 7,5 mm | 3 Hz – Amplitude 25 mm

Triaxialprüfmaschine (Zusatzinformationen hier)

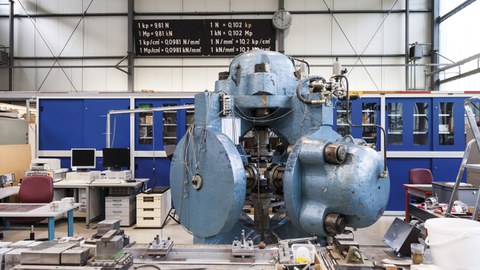

Das "Blaue Wunder" – die Triaxialprüfmaschine im OML

- Maximallast: 200 kN Zug oder 5 MN Druck je Achse

- Lasteinleitung: starre Platten oder Belastungsbürsten unterschiedlicher Geometrie

- Prüfkörpergröße: Standardgeometrie 10er Würfel, Quader mit 30 cm Kantenlänge möglich

Biaxialprüfmaschine (Zusatzinformationen hier)

- Maximallast: 100 kN Zug je Achse

Triaxialzelle

- maximale Vertikallast: 125 kN Druck

- maximaler Radialdruck: 5 MPa

- zylindrische Prüfkörper mit einem Durchmesser von 2,54 cm und einer Höhe von 5,08 cm

- Temperaturen bis 150 °C möglich

Horizontaler 20-MN-Belastungsrahmen (Zusatzinformationen hier)

- Maximallast: derzeit 10 MN (auf 20 MN aufrüstbar)

- maximale freie Prüflänge bei Druckversuchen: 5,0 m

- maximale freie Prüflänge bei Zugversuchen: 7,50 m

Horizontale Kettenzugmaschine

- Maximallast: 400 kN

- maximale Einspannlänge: 6 m

Biegeversuch an einem Holzfachwerkbinder

10-MN-Bauteilprüfmaschine

- Prüfkörpergröße bis B × L × H = 2,5 × 15,0 × 3,7 m

- maximales Prüfkörpergewicht: derzeit 60 t (auf 120 t aufrüstbar)

Split-Hopkinson-Bar (SHB) für hochdynamische Belastungsversuche

- Belastungsgeschwindigkeit: bis 35 m/s

- bei Druckversuchen: zylindrische Prüfkörper mit einem Durchmesser von 50 mm und einer Länge von 150 mm

- bei Spallationsversuchen: zylindrische Prüfkörper mit einem Durchmesser von 50 mm und einer Länge ≥ 200 mm

- kinetische Energie des Impaktors: bis zu 1,8 kJ

Zweiaxialer Split-Hopkinson-Bar (SHB) für hochdynamische Belastungsversuche

Biaxialer SHB im Mohr-Technikum

- max. Belastungsgeschwindigkeit: 35 m/s

- Prüfkörper: 60 × 60 × 60 mm

- kinetische Energie des Impaktors: je Achse bis zu 1,8 kJ

Kleiner Fallgewichtsversuchsstand

- Hmax = 5,0 m

- maximales Fallgewicht: 49,1 kg

Großer Fallversuchsstand (Fallturm) (Zusatzinformationen hier)

- mit Fallschlitten- und Beschleunigungssystem

- maximale Fallhöhe: Hmax = 11,0 m

- Freifallkonfiguration:

maximales Fallgewicht 2.500 kg, maximale Impaktgeschwindigkeit: 15 m/s - Beschleunigte Konfiguration:

maximales Fallgewicht: 160 kg, maximale Impaktgeschwindigkeit: 160 m/s

Fallschlitten

- Vorrichtungen für 3- und 4-Punkt-Biegeversuche für Standardprüfungen

- Modellstatik-Prüfstände zur Untersuchung von Stabwerk- und Flächenmodellen

- Kriechstände mit mechanischer oder pneumatischer Lasterzeugung

- Plattenprüfstand

- Fassadenprüfstand für Platten bis 2,4 × 2,4 m

- Versuchsstand für Schubversuche

- Ausstattung zur Durchführung von Versuchen mit variabler Temperaturbeanspruchung

- Versuchsstand zur Prüfung von Platten unter Windbeanspruchung

- Mehrere Steuerpulte

Für Bauwerksprüfungen ist eine große Anzahl von Belastungsrahmen vorhanden.

- Verschiedene Belastungsrahmen für In-situ-Prüfungen an Brücken, Decken, Stützen, Masten, Geländern etc.

- Ultraschallmessgerät

- Profometer 3 (Bewehrungsortung)

- Rückprallhammer

- (Video-)Endoskopiegerät

- Ausrüstung zur Entnahme von Bohrkernen

Zur Datenerfassung verfügen wir über eine umfangreiche Mess- und Speichertechnik, die verschiedenste Messgeräte und Messmittel einschließlich Photogrammetrie und Hochgeschwindigkeitskameras umfasst.

- Messverstärker

- MGC, MGCplus

- Quantum MX840

- Spider 8 - Vielstellenmessgerät UPM100

- Nahbereichsphotogrammetrie

- AICON-3D-System mit vier Kameras und Zubehör

- GOM ARAMIS 3D mit zwei Kameras (5 MP) und Zubehör

- GOM ARAMIS 2D mit vier Kameras (12 MP) und Zubehör

- Verschiedene Spiegelreflex- und Kompaktkamerasysteme - Transientenrekorder für Messungen bei Hochgeschwindigkeitsversuchen

- AOS-Messgerät für Faser-Bragg-Gitter-Sensoren

- Hochgeschwindigkeitskameras Photron Fastcam SA5

- Geräte zur Fernüberwachung von Messungen

- Datenlogger

- Dehnmessstreifen

- Induktive Wegaufnehmer

- Faser-Bragg-Gitter

- Dehnungs- und Beschleunigungsaufnehmer

- Dynamische Kraftsensoren

- Laservibrometer für berührungslose Weg- und Geschwindig-keitsmessung über große Distanzen

- Thermoelemente und Feuchtesensoren (Luftfeuchte)

- Extensometer

- Seilzugsensor

- Windmesser

- Nivelliergerät

- Theodolit

- Verschiedene Entfernungsmessgeräte

- Neigungssensor: Winkelbestimmung bis +/– 30°

- Inclinometer LSOC-0120: Winkelbestimmung bis +/– 3°

- Verschiedenste mechanische Längenmessgeräte, u. a. Messuhren, Setzdehnungsmesser (Bauart Pfender/Setzdehnungsmesser), Messschraube bzw. Mikrometerschraube

- Hand-Held-Shaker

- Magnet-Messstativ

- Federzugkraftmesser

- Verschiedene Kraftmessbügel

Darüber hinaus finden Sie hier einige Angaben zu unserer sonstigen Ausrüstung.

Brückenkrane

- Mohrhalle: Tragkraft je 5 t

- Technikum, Bereich Betonierhalle: Tragkraft 5 t

- Technikum, Bereich Versuchshalle: Tragkraft 10 t

Weiteres

- Gabelstapler (Tragkraft: 3,5 t)

- Schweißerausrüstung (elektro und autogen)

- Mobile Öldruckaggregate

- Aggregat zum Sandstrahlen

- Schwerlastwagen, Tragkraft: 60 t

- Geräte zum Anheben und Verschieben von bautechnisch relevanten Lasten bis 120 t durch Einsatz hydraulischer Hebetechnik

- CNC-Fräse mit 3-Achs-Bearbeitungsraum

- 3D-Drucker zur Herstellung von maßgefertigten Zubehörteile

Schwertransport im OML: der Split-Hopkinson-Bar bekommt ein neues Zuhause