Jun 08, 2018

DFG has Approved Research Training Group 2430 “Interactive Fiber Rubber Composites”

Subproject Leaders of the Research Training Group 2430 " Interactive Fiber Rubber Composites"

Dresden researchers want to generate an innovative class of materials involving the intergration of actuator and sensor networks into flexible fiber-reinforced composite materials. For this purpose, the Deutsche Forschungsgemeinschaft (DFG) has recently approved a new Research Training Group 2430 termed "Interactive Fiber Rubber Composites" at TU Dresden in collaboration with the Leibniz Institute of Polymer Research Dresden. Prof. Chokri Cherif from the Institute of Textile Machinery and High Performance Material Technology (ITM) of TU Dresden acts as spokesman.

Within the upcoming 4.5 years, equipment and material in addition to PhD students will be funded, who will participate in 11 interdisciplinary subprojects.

It is aimed at the simulation-based development of smart material combinations to create so-called self-sufficient fibre rubber composites. For this purpose, actuators and sensors are directly integrated into these structures instead of adding them subsequently. Hence, systems become more robust and complex deformation patterns can be specifically adjusted, whereas these change are produced in a reversible and contactless manner. At TU Dresden in general and at ITM in particular, extensive research efforts have been dedicated to this subject area in recent years.

Creating a new materials class "Interactive Fiber Rubber Composites"

Fiber-reinforced composites are increasingly used for moving components due to their high specific stiffness and potential in terms of the customized modification of properties. As adaptive functionalities are directily integrated into these innovative materials, the need for subsequent actuator placement is eliminated, and the system robustness is significantly enhanced. Textile-based actuators and sensors represent a particularly promising approach- and have therefore been in the centre of attention at ITM - because they can be intregrated into fiber-reinforced composites during the manufacturing process.

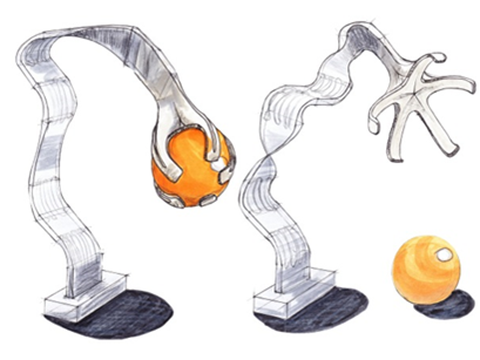

The innovative feature of this project lies in the generation and scientific permeation of Interactive Fiber Rubber Composites (I-FRC), a materials class that is not yet available and characterized by structure-integrated actuator and sensor networks. Their development will, for example, allow for the reversible and contactless adjustment of geometric degrees of deformation for mechanical components; thus, various environmental requirements can be met in a quick and precise manner.

Due to their innovative properties, Interactive Fiber Rubber Composites are suitable for numerous fields of application, such as mechanical engineering, vehicle construction, robotics, architecture, orthotics, and prosthetics. Potential applications include their use in systems for precise gripping and transportation processes (e.g. hand prostheses, automated lids, shapeable membranes) and structural components (e.g. trim tabs for ground- and watercraft).