Optimization of mercury oxidation

Title:

Fuel variable optimization of mercury oxidation in the context of the bromine additive process

Research associate:

Dipl.-Ing. Anne-Christin Kropp

Duration:

04/2017 – 07/2020

Funding institution:

Sächsische Aufbaubank

Background and motivation:

Mercury (Hg), which in Germany is mainly emitted by thermal power plants and other incineration plants (2013: 72 %), has a high toxic potential. Especially mercury-methyl-compounds, which accumulate in marine organisms, pose a risk of serious consequences for the central nervous system (minamata disease).

One process for reducing mercury emissions from coal-fired power plants is the so-called bromine additive process with the addition of CaBr2 as oxidant. This process has been part of investigations in industry and research for a little more than 10 years, especially in the USA. Good results have been achieved there. Due to considerable differences in fuel composition and plant design, a direct transfer of this technology and the results to German coal-fired power plants is not possible. In order to gain a deeper understanding of the process, a systematic investigation of the influencing parameters of mercury oxidation is necessary, by which an optimal mercury separation can be achieved.

In this research project, the understanding of the process is to be developed and the resulting optimization potential is to be shown. By this investigation a definition of the necessary process parameters for the oxidation of mercury by suitable additives depending on the boundary conditions resulting from the respective fuel and the respective plant configuration will be worked out.

Working package 1: Creation of the test matrix

Working package 2: Adaptation of the existing test facility to the current measuring task

Working package 3: Measurement campaigns for systematic investigation of the main parameters influencing mercury oxidation

Working package 3.1: Experiments with the pure gas phase

Working package 3.2: Experiments with addition of ashes

Working package 4: Experiments with catalysts

Working package 5: orienting experiments with dry lignite

Working package 6: Fuel-independent optimization strategy

Working package 7: Result evaluation and report

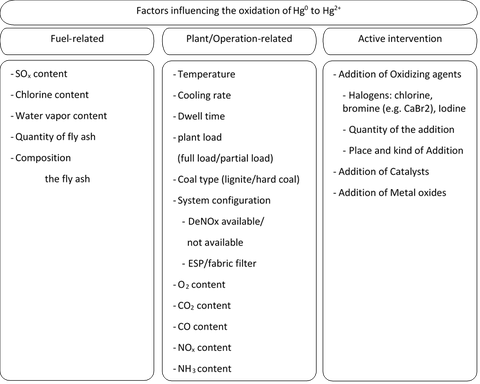

Figure 1: Influencing parameters of mercury oxidation

Publications and presentations:

- Herrmann, D.; Köhler, M.; Ohle, A.; Beckmann, M.: Einflussparameter auf die Oxidation von Quecksilber bei der Verbrennung in Kohlekraftwerken. In: Beckmann, M. (Hrsg.): Emissionsminderung in Kraftwerken 2017 - Grenzwerte, Messtechnik, Praxiserfahrungen. Freiberg: SAXONIA Standortentwicklungs- und -verwaltungsgesellschaft mbH, 2017, S. 43-53. ISBN 978-3-934409-77-4

- Herrmann, D.; Ohle, A.; Köhler, M.; Beckmann, M.: Einflussparameter auf die Quecksilberoxidation in der Rauchgasreinigung von Kraftwerken. Poster bei der Jahresversammlung der Fachgruppe Gasreinigung der ProcessNet, 19./20.02.2018

-

Bittig, M.; Klöfer I.; Herrmann, D.; Ohle A.: Quecksilberabscheidung in REA-Wäschern. Ein Abgleich zwischen dem Stand der Forschung und den Erfahrungen aus der Praxis. In: Beckmann, M. (Hrsg.): Emissionsminderung in Kraftwerken 2018 - Emission Reduction In Power Plants. Freiberg: SAXONIA Standortentwicklungs- und -verwaltungsgesellschaft mbH, 2018, S. 141-151. ISBN 978-3-934409-82-8