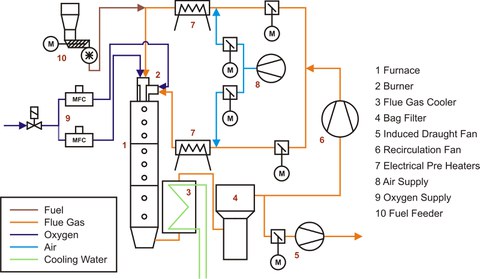

50 kWtherm dust firing test plant

Plant Features

- test facility with an indirect firing system for pulverized fuels

- cylindrical combustion chamber with a roof burner, consisting of five single segments with an inner refractory lining and air-cooled walls

- operations: conventional combustion with air/combustion with pure oxygen ("oxyfuel")

- flue gas circulation for ensuring realistic oxyfuel conditions at combustion

- pneumatic fuel transfers to the burner with air or circulating flue gas

- different types of burners available (stream burner, swirl burner); burner optimization with CFD

- additional gas burner for ignition firing or for combustion support

- good accessibility for flame observations with standard probes through numerous measuring ports

- modern facility control system with graphic user interface and constant capture of measure data and flue gas composition

- options for additional additives like Ash, SO2, H2O, HgCl2

- flue gas measurement of (Hg, O2, CO2, H2O, NO, NO2, N2O, SO2, NH3, HCl)

- possible combination with pilot plant for flue gas desulphurization

Technical parameters

| Thermal power output: | 50-60 kWth |

| Combustion chamber dimension: | Inner diameter 0.29 m, length 2.50 m |

| Amount of fuel (depending on calorific value): | About 6 - 12 kg/h pulverized fuel or 2 - 5 m3/h (natural gas) |

| Oxygen feed rate: | 0-20 kg/h |

| Flue gas circulation: | 20-120 kg/h |

| Air/recirculation temperature: | 100-400 °C |

| Flue gas output temperatures: | 550-750 °C (end of combustion chamber) 150-250 °C (after flue gas cooler) |

Person responsible: Dipl.-Ing. Christoph Bergmann