Batch-Reaktor

Batch reactor

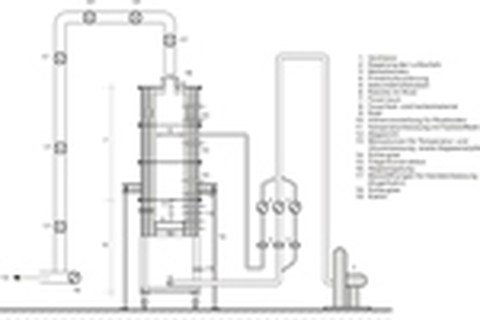

The batch reactor of the Chair for Energy Process Engineering is a pilot plant on the technical scale.

It serves the determination of fuel reaction characteristics, e. g. burnout and ablation properties of fuel can be investigated in the batch reactor. The characteristics determined complete the chemical, calorific and mechanical properties gathered in the laboratory, in order to examine the fuel’s behavior in the process.

In the batch reactor, fuel is added discontinuously. The singular intermediate steps of the process thereby precede temporally one after the other in a transient operation. The process-specific conditions of thermal treatment of fuel in the batch reactor can be specifically varied by control of the intermediate steps of solid material turnover (pyrolysis, gasification and combustion).

Compared to the laboratory, larger quantities of fuel having a large grain size (mostly untreated original grain size) can be investigated, which makes representative examinations, also of heterogeneous fuels (waste, substitute fuels), possible.

Technical parameters

| Fuel bed: | variable fuel type max. amount of fuel: ca. 30 l |

| Combustion chamber: | combustion chamber wall temperature: 800-950 °C heating with a gas burner 40 kW |

| Parameter variations: | primary air volume flow, temperature of primary air, secondary air volume flow, local and temporal air stages, relation primary air/secondary air etc. |

Publications on the pilot plant:

- AiF-Vorschungsvorhaben: Substitution von Regelbrennstoffen durch Ersatzbrennstoffe. AiF-Nr. 14894 BG. Beckmann, M., Bauhaus-Universität Weimar; Scholz, R., Technische Universität Clausthal, Institut für Energieverfahrenstechnik und Brennstofftechnik; Flamme, S., Institut für Abfall, Abwasser, Site und Facility Management e. V., Ahlen; Seifert, H., Forschungszentrum Karlsruhe, Institut für Technische Chemie, Eggenstein-Leopoldshafe.

- Beckmann; M.; Krüger, S.; Gebauer, K.; Pohl, M.; Spiegel, W.; Müller, W.: Methoden der Korrosionsdiagnose bei der Verbrennung schwieriger Brennstoffe. Thomé-Kozmiensky, K. J. und Beckmann, M. (Hrsg.): Energie aus Abfall, Band 6. Neuruppin: TK Verlag, 2009, S. 443-460, Berlin.

Pilot plant for processing of fuel gas from biomass gasification