Kombivergaser - Versuchsanlage zur Biomassevergasung

pilot plant for biomass gasification in a two-step reactor, including gas processing and gas utilization in a cogeneration unit for electricity and heat

The Chair for Combustion, Heat and Mass Transfer is optimizing a two-step gasification reactor for the generation of a high quality fuel gas at the Schwarze Pumpe site in cooperation with Nagel Ingenieurbau Ltd.

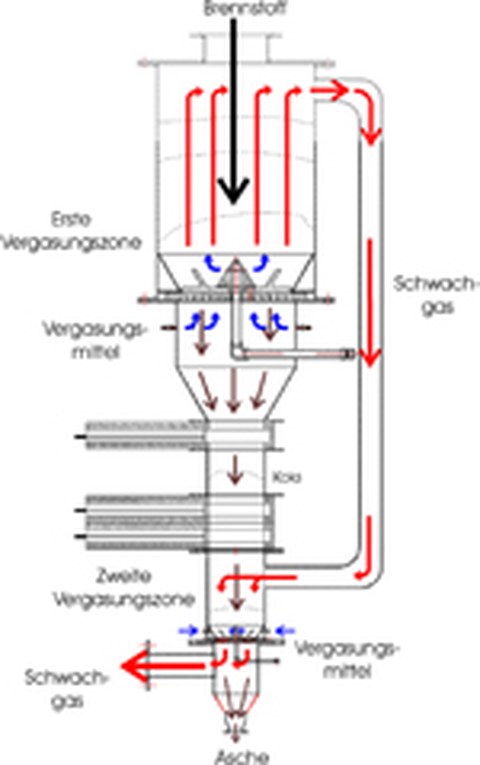

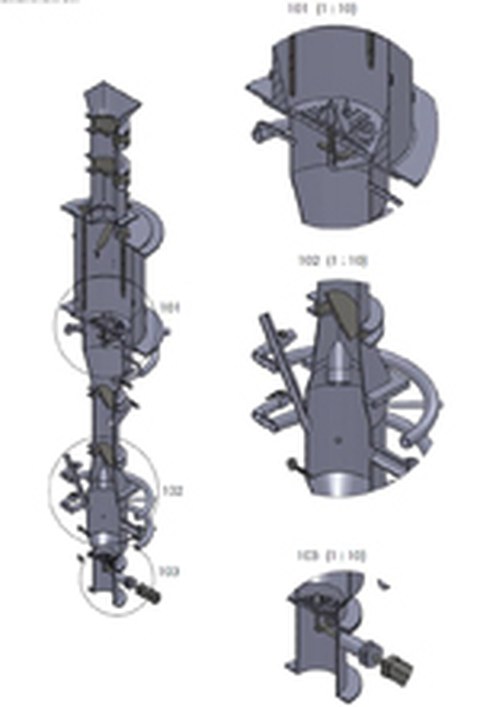

The gasifier consists of a counter-current and a downstream co-current reactor.

The idea behind this version is to utilize the pros of both principles. Noteworthy is the good scalability of a counter-current reactor with regard to the dimensions of the applicable fuels and because of the location of the resulting reaction zones and a high transformation rate in the co-current reactor.

In the first step, the existing gasifier is constructively optimized on the basis of theoretical calculations and first investigation results, in order to realize an operating condition which is as stable as possible. In the second step, development and physical implementation of a gas cleaning with the use of non-catalytic partial oxidation with regenerative heat recovery takes place. The gas resulting from the process is cooled after subsequent cleaning and converted into electricity by application of a CHP. In order to increase the energetic balance of the overall process, the resulting waste heat is supposed to be redirected into the overall process at suitable points.

Technical parameters

| Combined counter- and co-current gasifier | |

| Rated fuel thermal output: | 100 kW |

| Fuel mass flux: | ca. 25 kg/h |

| fuel: | Holzhackschnitzel (andere Biomassen) |

| Gasification agent: | Luft (18 bis 23 Nm³/h) |

| Gas flow rate: | 50 m³i.N./h |

| Analysis of gas quality: | CO, CO2, H2, CH4, O2 |

Plant site

Nagel Ingenieurbau Ltd.

Schwarze Pumpe