Reaktionsrohr nach FIELD

Drop tube reactor

The reactional kinetic investigations of solid fuels in the drop tube reactor serve the gathering of basics for both the technical and constructive design or optimization of pulverized fuel firing systems, and the corresponding mathematical and CFD-modelling, such as with Ansys FLUENT.

The drop tube reactor consists of a heat resistant steel pipe with an inner diameter of 49 mm. The electric heating takes places in five segments that are controlled separately and can, if necessary, be adjusted to various temperatures. In each heating segment, there are two powerful heating elements that are able to generate an excess temperature of up to 1.700 °C.

Either air or artificial gaseous mixtures are used as reaction gases which can be produced at a gas mixing station from bottled gas (single gas). Reaction gas is preheated in an equally electrically heated gas preheater on the identical temperature of the reaction tube and flows laminarily through the steel tube from the top to the bottom. The dosing of pulverized fuel is implemented by a vibrating distributor that is situated on top of the stilling tank of the gas supply.

In order to avoid premature ablation, the addition conduit of the stilling tank is cooled by a water cooler.

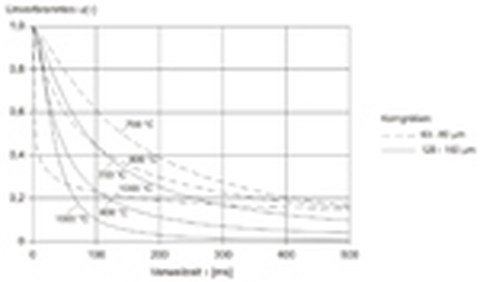

The fuel is continuously added to the reaction tube, ignited and burnt. During the investigations at the drop tube reactor, the primary influence parameters on the combustion process, such as grain size of the pulverized fuel, oxygen content in the reaction gas and the reaction temperature are varied independently of each other under conditions similar to those in a steam generator that is singular corn combustion at high speed heating. The combustion remnants are collected after different residence times with a water-cooled sampling probe for laboratory examination. The residence time is calculated with the gas flow rate in the reaction tube. The ablation behavior at constant combustion conditions allows a regression analysis for the apparent reaction order and speed.

The reaction-kinetic data for the Arrhenius approach, such as the frequency factor and the activation energy, can be determined by the apparent reaction speed at different combustion temperatures.

Besides the reaction kinetics, degasification, pollutant formation, combustion and slagging behavior of the pulverized fuel can be investigated. Therefore, the apparatuses must be adjusted to the sample extraction.

Technical parameters

| throughput pulverized fuel: | 2 - 4 g/h |

| throughput reaction gas: | 1,0 - 3,0 Nm³/h |

| range of examination temperatures: | 600 - 1.300 °C |

| inner diameter of reaction tube: | 49 mm (57 x 4) |

| heated length of reaction tube: | 2,9 m |

| residence time: | 0,5 - 3 s |

| flow rate: | 0,8 - 5 m/s |

ablation of a coal dust sample depending on grain size and combustion temperature

flow sheet of ablation examinations