Versuchsstand Pelletfeuerung

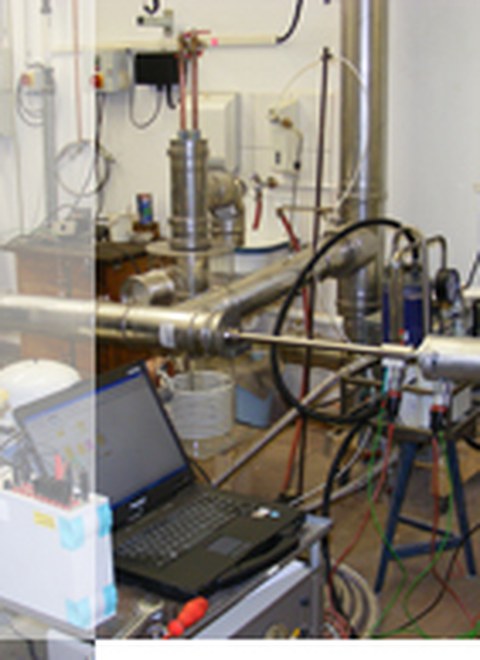

Pellet firing test plant

The pellet firing test plant of the Chair for Combustion, Heat and Mass Transfer serves the examination of ablation behavior of pelletized fuels in a commercially available domestic small furnace.

Furthermore, retrofit kits for the reduction of particulate emissions (e. g. electrical precipitators, washers, etc.) can be examined with regard to their effect. Therefore, several temperature and pressure sensors for determining the flue gas composition are installed at the firing. Total dust and particle size distribution can be measured for determining dust emissions.

The core of the pilot firing facility constitutes the pellet heating system Pellematic PE15 portrayed in picture 1. It is a boiler for warm water generation, which is usually used as heating circulation water of buildings and for domestic water heating. The power range of the firing lies between 5 and 15 kW. Fuel transport is implemented originating from a daytime chemical tank with a screw pipe conveyor to a burner plate. Commercially available wood pellets are intended to be used as regular fuel with accordance to DIN 51 731. Furthermore, there is the possibility of burning other pellets, such as grain pellets for inquiry purposes. The flue gas is led outside with a flue gas ventilator and through flue gas pipes with limited action.

Projects

| 2008-2010 | Development and testing of a retrofit kit for reducing particulate emissions of singular fireplaces with solid fuels by using heating value technology; AiF ZIM |

| 2007-2008 | Development and testing of prototypes for exhaust gas heat exchangers and an advisory system for residual heat utilization of small furnaces with solid fuels; AiF ProInnoII |

| 2007-2008 | Reduction of particulate emissions by optimization of combustion chambers and innovative exhaust gas cleaning or washing; FNR |

Pellet firing test plant;

front view pellet vessel with storage tank