EAC+

Sustainable Electric Architecture Casings

The aim of EAC+ is to develop recyclable economically and technically competitive casing structures that have a high potential to be used in a wide range of industries and at the same time meet the high electromagnetic requirements of electromobility. The casing structure will be realized as a hybrid component in which a thin metal sheet provides the electromagnetic compatibility (EMC) and the thermoplastic component transfers the mechanical loads. Such casings are intended for use in a wide range of industries, from mobility to renewable energy technology.

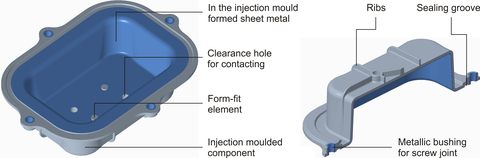

A new type of hybrid injection moulding is being developed with the EAC+ project partners. This combines injection moulding and metal forming in a single process. The innovation of the EAC+ technology is based on the new design, the unique process and a broader selection of materials. These enable the production of highly integrative, low-CO2 or CO2-neutral and recyclable products that are lighter and more cost-effective than today's solutions while meeting the high requirements for EMC. The solutions are also characterized by significantly reduced production steps, low assembly costs, improved acoustic properties and significant energy and material savings. In order to objectively evaluate and prove the sustainability of these innovations, a life cycle analysis is carried out, which enables a holistic assessment of the environmental impact from raw material to recycling.

Generic functional model in metal-plastic hybrid design.

01.12.2021–30.11.2024

Consortium leadership

Project partners

- ZF Friedrichshafen AG

- Fahrzeugelektrik Pirna GmbH & Co. KG

- Institute for Processing Machines and Recycling Systems Technology (IART) at the TU Bergakademie Freiberg

- Institute of Power Transmission and High Voltage Technology (IEH) at the University of Stuttgart

- Institute of Manufacturing (IF) at the TU Dresden

© TUD/ILK

© TUD/ILK

Chair of Lightweight Systems Engineering and MultiMaterial Design

NameProf. Dr.-Ing. habil. Maik Gude

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Lightweight Engineering and Polymer Technology

Visitors Address:

DÜR, Floor 0, Room 71 Holbeinstr. 3

01307 Dresden

Deutschland

- Dr. Juliane Troschitz (Joining Technologies)

Publications Juliane Troschitz | TU Dresden - Levin Schilling (Neutral Lightweight Engineering|Lightweight Design)

Publications Levin Schilling | TU Dresden - Fabin Folprecht