LOBO

Local in-situ functionalization of large-format 3D printed components using mobile injection moulding technology

The LOBO project aims to research and test the innovative combination of large-format additive manufacturing (LFAM) technology and mobile injection molding. The objective is to overmould large-volume 3D printed components locally and functionalize them with connecting elements, for example. In particular, the scientific and technical questions regarding pre-treatment methods, material interactions and control and software-side process linking are to be answered. The investigations will focus on researching the complex property relationships between process, material and structure. To this end, the existing challenges of the LFAM process in terms of interaction with mobile injection molding on a laboratory scale are to be identified and solution strategies for use in relevant application environments are to be developed. The overall aim of the project is to develop a profound process understanding of the novel combination technology in order to enable it to be used in a variety of application fields.

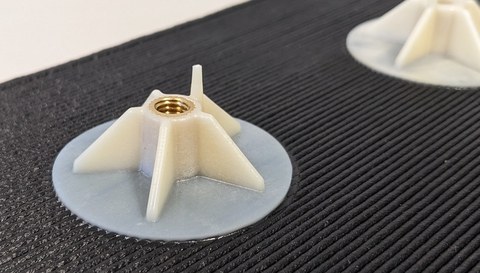

Thermoplastic functional element with embedded metallic thread insert, which was joined to a large format additive manufacturing (LFAM) structure using mobile injection molding technology.

01.01.2024 – 31.12.2026

European Regional Development Fund (ERDF) in Saxony: Funding program for joint R&D projects 2021-2027

roject number: 100693463

Sächsische Aufbaubank (SAB)

© Christian Hüller

© Christian Hüller

Chair of Function-integrative Lightweight Engineering

NameProf. Dr.-Ing. Niels Modler

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Lightweight Engineering and Polymer Technology

Visitors Address:

DÜR, Floor 0, Room 69 Holbeinstr. 3

01307 Dresden

Deutschland

- Martin Pohl (Joining Technologies)

Publications: Martin Pohl | TU Dresden