NEAPEL

Numerical and experimental analysis of damage-dependent gas transport in thermoplastic composites

The Neapel project is investigating the damage-dependent gas permeation properties in FRP structures to create the basis for recyclable and efficient hydrogen pressure storage systems for mobility applications made of thermoplastic composites. The Institute of Lightweight Engineering and Polymer Technology (ILK) focuses on developing experimental methods, while the Institute of Solid Mechanics (IFKM) at the TU Dresden is developing a phase field damage model for FRP.

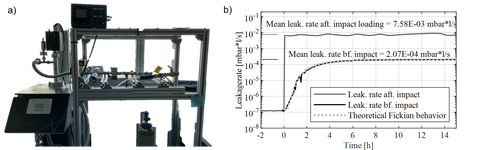

Current pressure vessels rely on a metal or plastic liner as a permeation barrier, complicating maintenance and recycling. Thermoplastic FRP-type V tanks offer an efficient solution by combining barrier properties and load-bearing capacity, with the prerequisite that they do not form damage networks under high internal pressure loads, which would allow leaks. To this end, the ILK has developed a high-pressure permeation test rig that enables the permeation properties of polymers, FRP and multilayer structures to be determined (Fig. 1).

Another focus was on methods for characterizing damage networks. In this regard, an optical deformation measurement (DIC) method has been developed at the meso level, facilitating the investigation of crack formation and growth. The integration of suitable contrast agents in CT scans, in conjunction with the employment of artificial neural networks (UNet), enables the quantitative evaluation and description of crack networks in three dimensions, even in cases where scan resolution is limited (Fig. 2).

Fig. 1: High-pressure permeation test rig.

Fig. 2: Segmentation of a CT volume using a convolutional neural network trained with a 3D-UNet approach.

01.03.2022 – 28.02.2025

© TUD/ILK

© TUD/ILK

Chair of Lightweight Systems Engineering and MultiMaterial Design

NameProf. Dr.-Ing. habil. Maik Gude

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Lightweight Engineering and Polymer Technology

Visitors Address:

DÜR, Floor 0, Room 71 Holbeinstr. 3

01307 Dresden

Deutschland

- Jan Condé-Wolter (Thermoplastics Processing)

Publications Jan Condé-Wolter | TU Dresden

- Christian Düreth (Testing Methods and Material Models)

Publications Christian Düreth | TU Dresden