SFB/TRR285-C04

Local and integral in situ analysis of process- and operation-related damage effects of joints

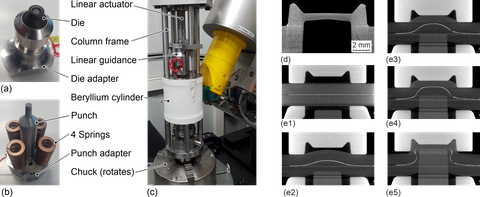

In FP 1 of Project TRR285, Subproject C04, a non-destructive method for examining mechanical joining connections under load through in situ CT was developed to investigate deformation and damage phenomena. To ensure a high image quality during in situ CT scanning of clinching with aluminum joining partners, a multimaterial tool comprising a punch made of Si3N4 and a die made of a high-strength titanium alloy was necessary (Figure a and b). Conventional testing machines reduce the CT scan quality due to their columns. In the developed testing set-up, however, consistently high-quality X-ray projections were ensured using a beryllium cylinder (Figure c). Due to the high surface pressure between the two aluminum sheets at the clinch point, the interface is partially unidentifiable in the CT images (Figure d). In order to fully capture the deformation state, a tin foil was introduced between the sheets. With this novel method, for the first time, the development of deformation phenomena at the clinch point could be traced through CT scans conducted at various stages during the clinching process (Figures e1 – e5). In FP 2, the procedure will be extended to fiber-reinforced plastics. This entails investigating their relaxation behavior as well as joining and loading processes at elevated temperatures.

(a and b) In situ CT tools, (c) testing device with beryllium cylinder, (d) CT image of a clinch point with partially invisible interface, (e1-e5) CT images from the in-situ CT measurement of the clinching process at various displacement levels.

01.03.2022 – 28.02.2025

© TUD/ILK

© TUD/ILK

Chair of Lightweight Systems Engineering and MultiMaterial Design

NameProf. Dr.-Ing. habil. Maik Gude

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Lightweight Engineering and Polymer Technology

Visitors Address:

DÜR, Floor 0, Room 71 Holbeinstr. 3

01307 Dresden

Deutschland

- Jan Condé-Wolter (Thermoplastics Processing)

Publications Jan Condé-Wolter | TU Dresden

- Christian Düreth (Testing Methods and Material Models)

Publications Christian Düreth | TU Dresden